Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

smoothride said:You do need that notch in the first pic in your new plates to make the arms work to hold up the track when the suspension goes down.

You are correct Smoothride.

I forgot to mention that the hole's for the swingarm/cross-shaft remain unchanged.

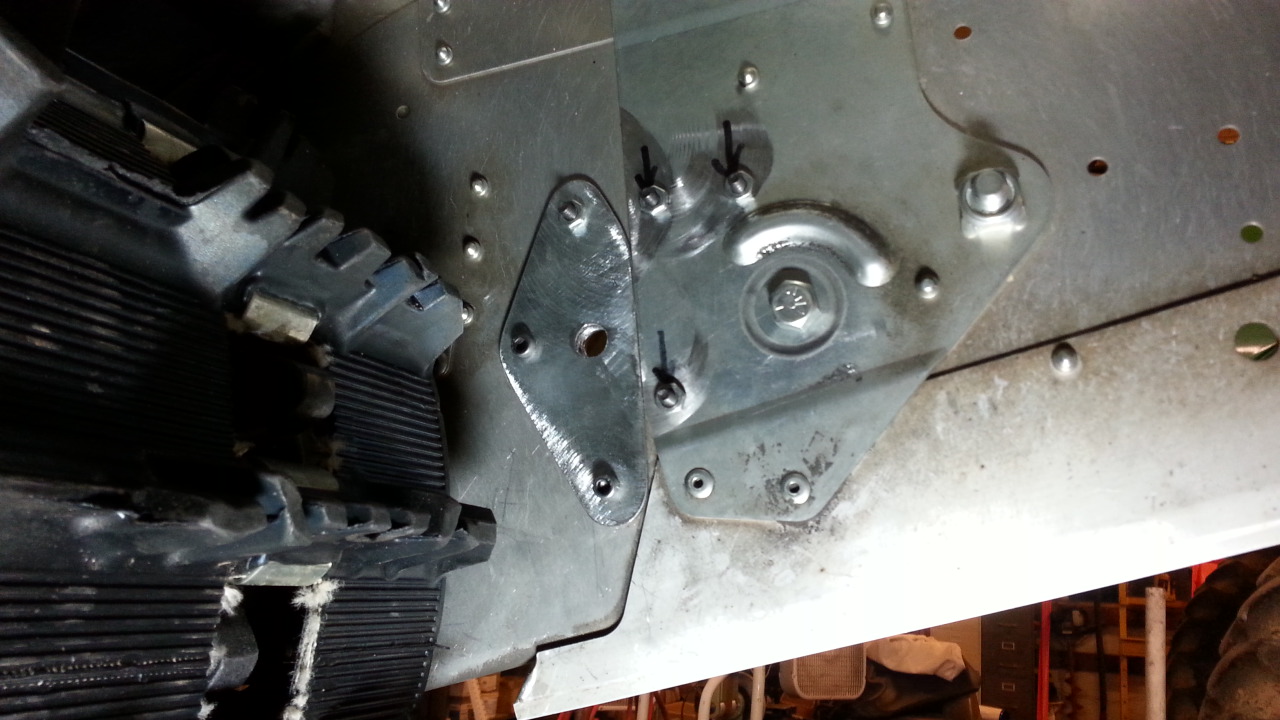

Here are a few more views of the right drop bracket showing where I drilled (4) new holes and welded the original shut. The left bracket was drilled the same:

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

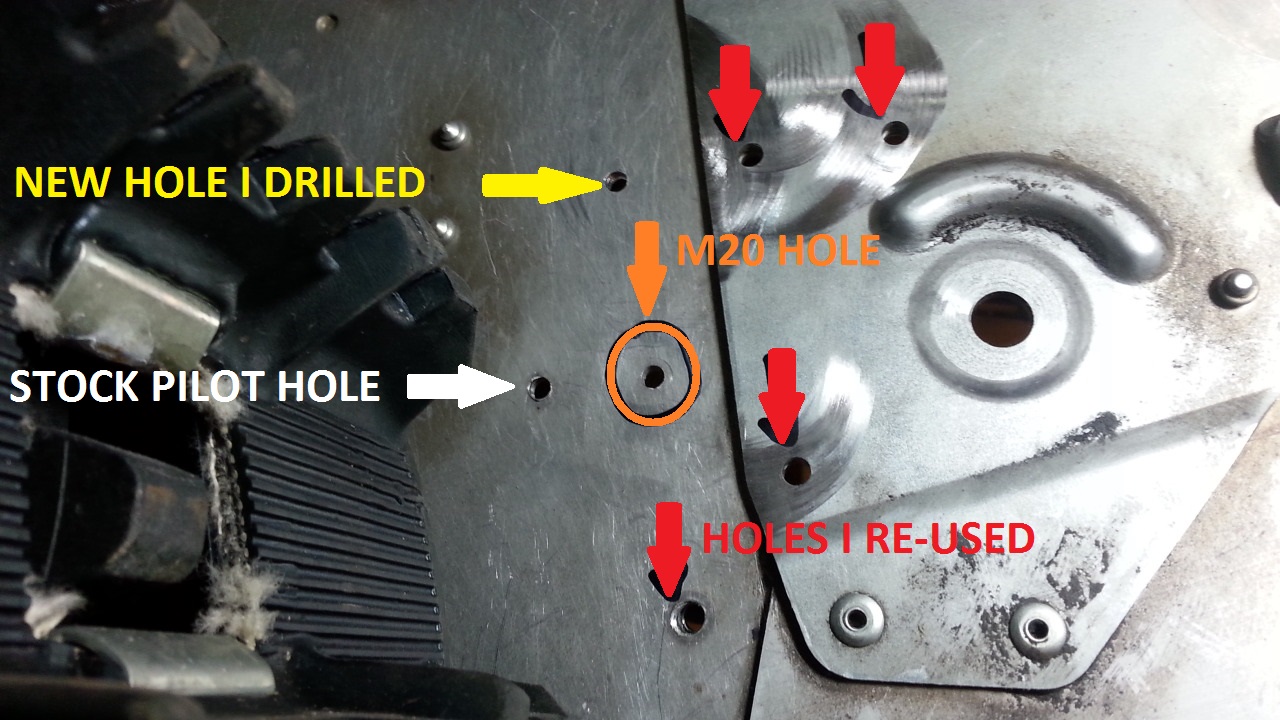

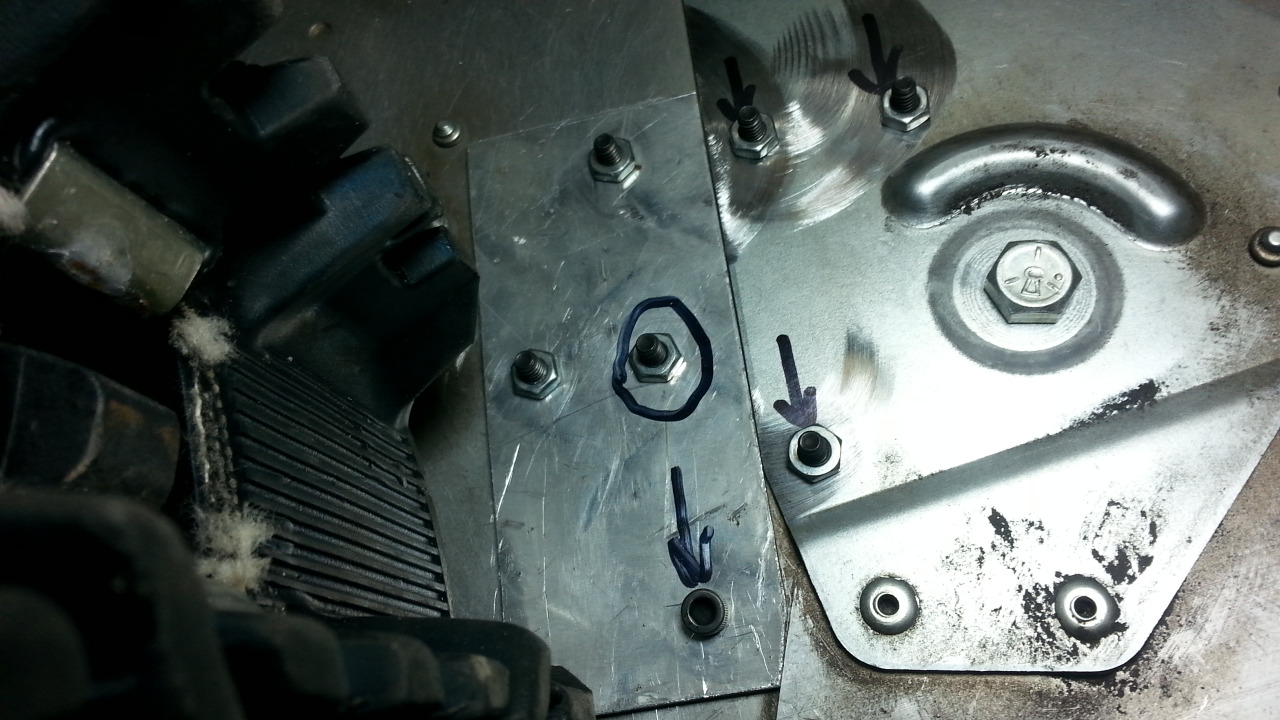

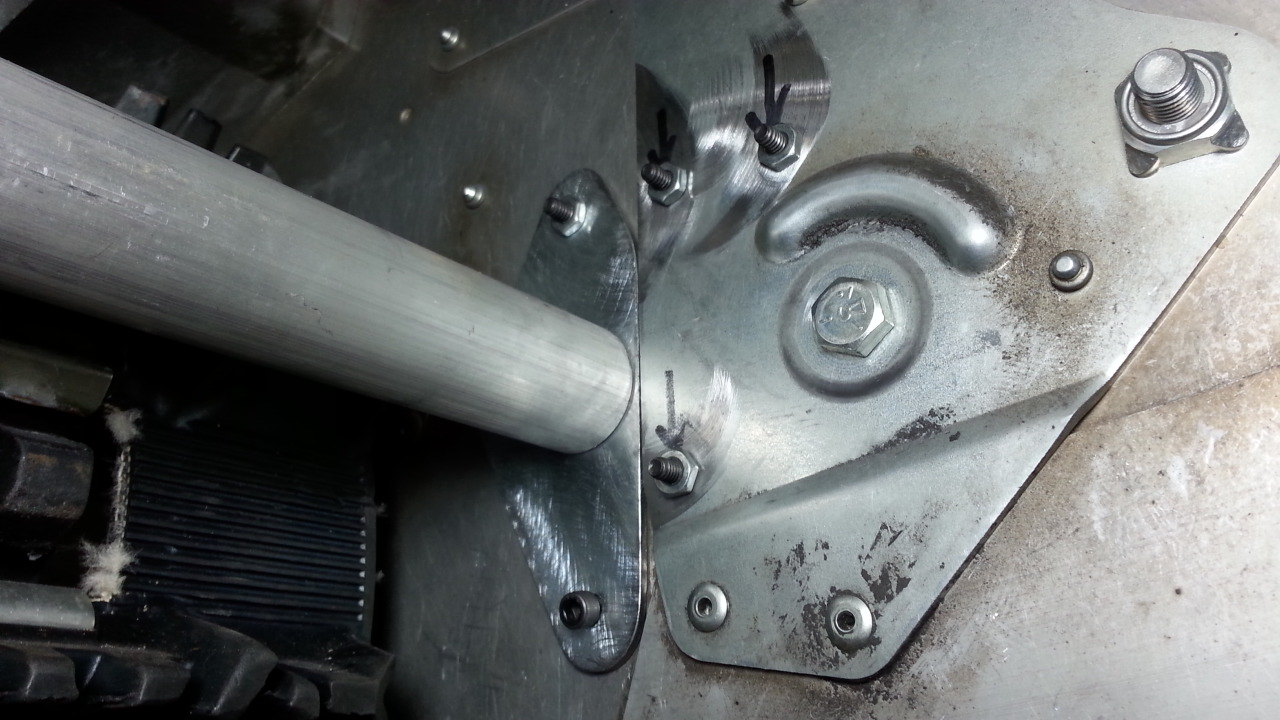

I started working on the area for the front swingarm. Fast sent tunnel support plates that rivet inside the tunnel for this, but I chose to make my own out of 12ga steel and use some existing rivet holes in the chassis. I'm also making plates for the outside of the tunnel that will tie into the stock front swingarm bracket for added rigidity. The colored arrows show which stock holes I'm reusing and the circle shows which hole will be drilled to 7/16" for the swingarm.

I only drilled one new hole for this area (yellow arrow).

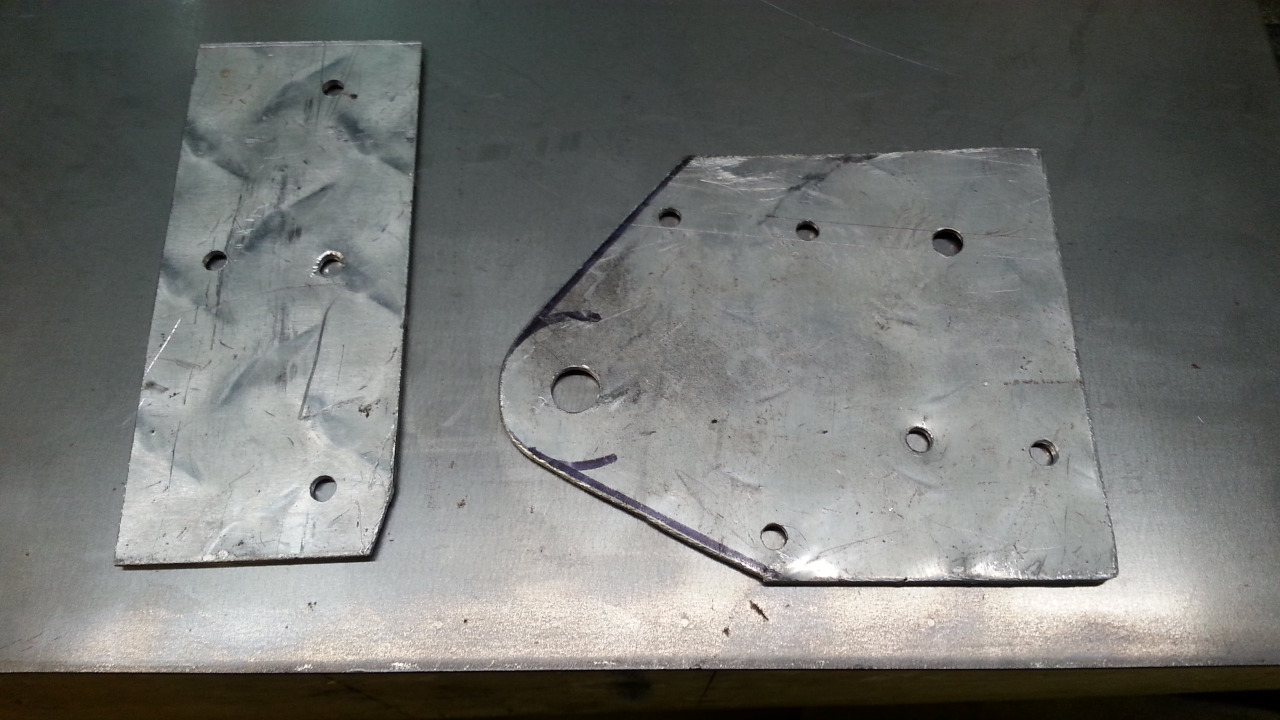

These pictures show the templates I first made out of aluminum to get the size and shape of tunnel support plates I needed. I then used them as drill guides when I cut the final brackets out of steel.

I only drilled one new hole for this area (yellow arrow).

These pictures show the templates I first made out of aluminum to get the size and shape of tunnel support plates I needed. I then used them as drill guides when I cut the final brackets out of steel.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

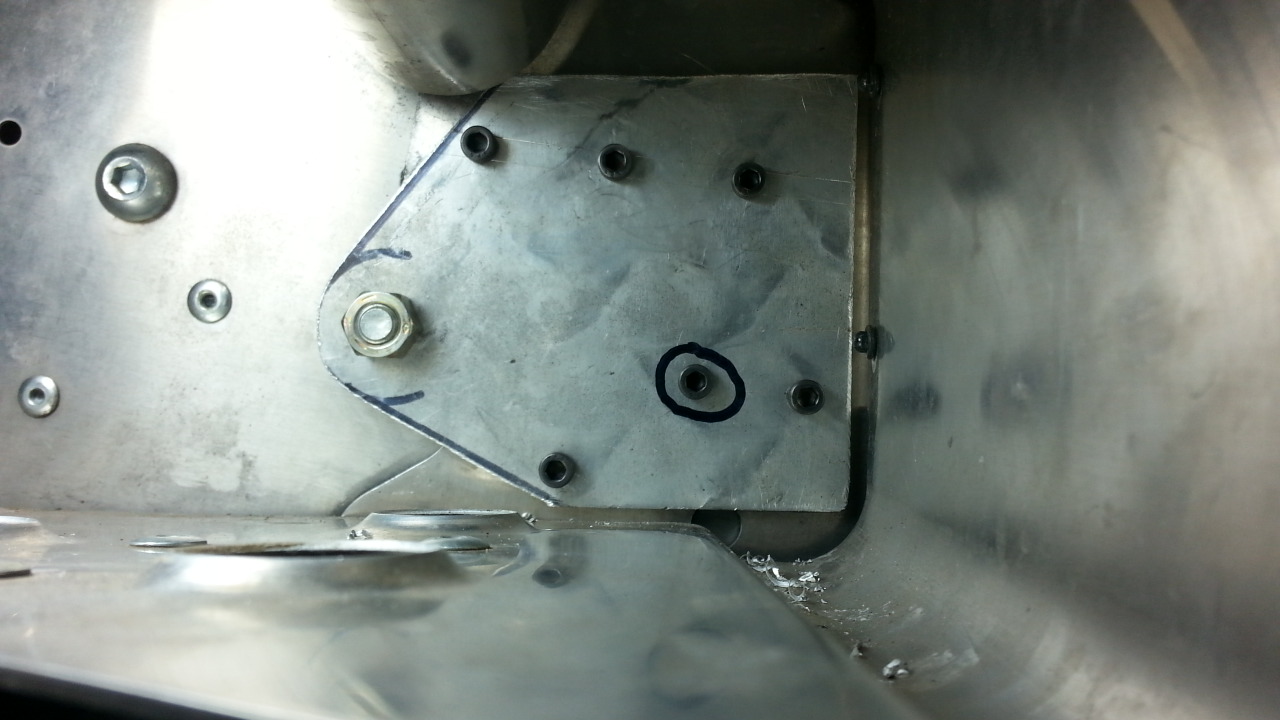

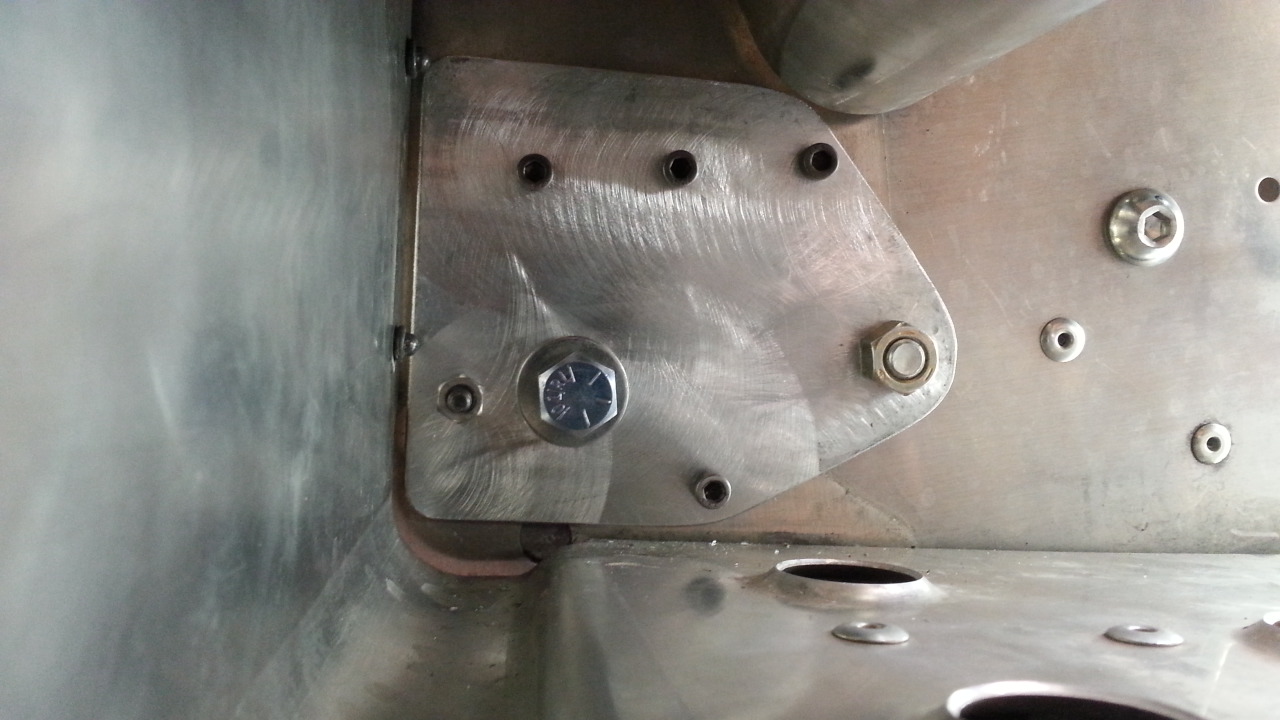

Here are a few more pictures of the finished front arm support plates.

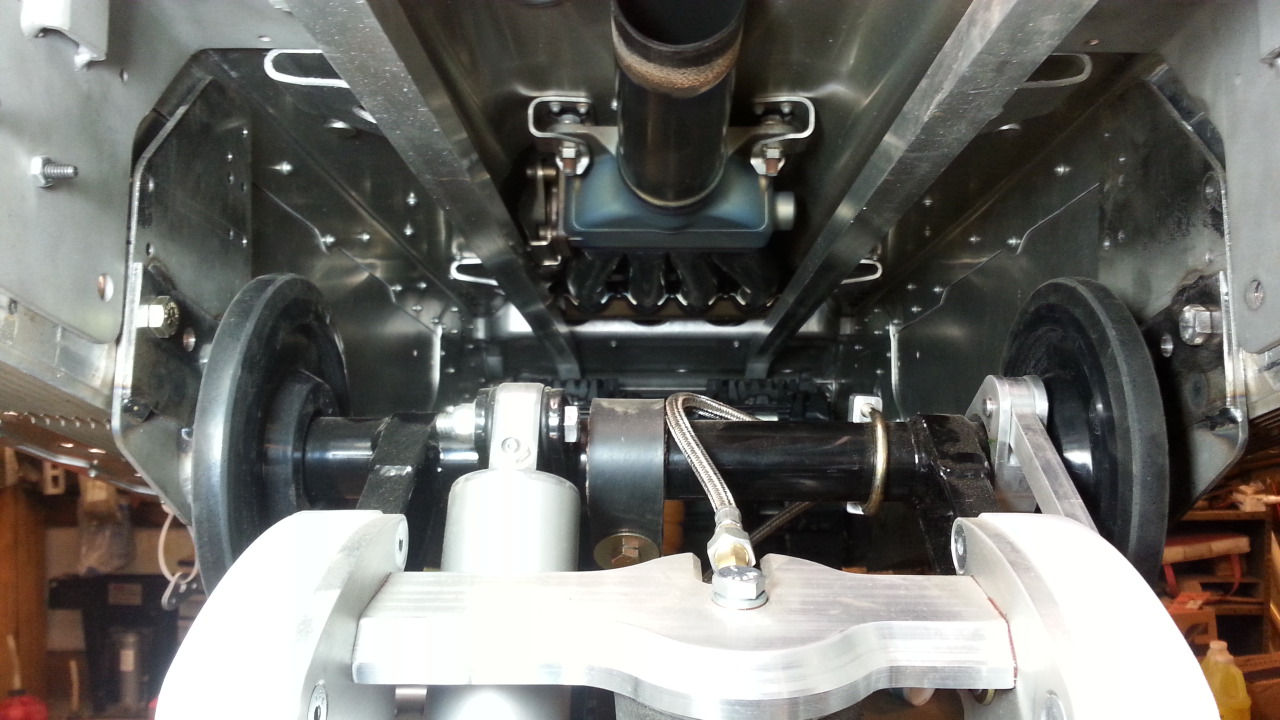

I drilled the 7/16" holes through the footwell and test fit the front cross shaft. Next step is to test fit the entire skid before I powder coat the parts.

I drilled the 7/16" holes through the footwell and test fit the front cross shaft. Next step is to test fit the entire skid before I powder coat the parts.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

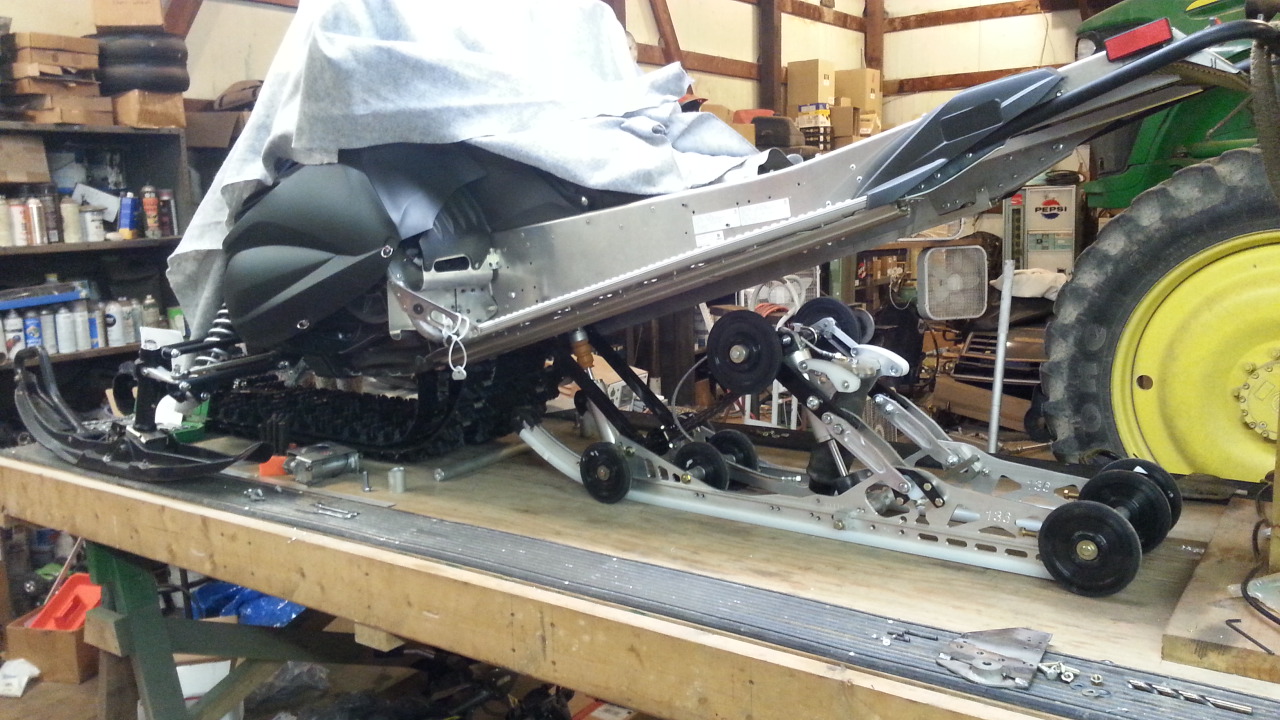

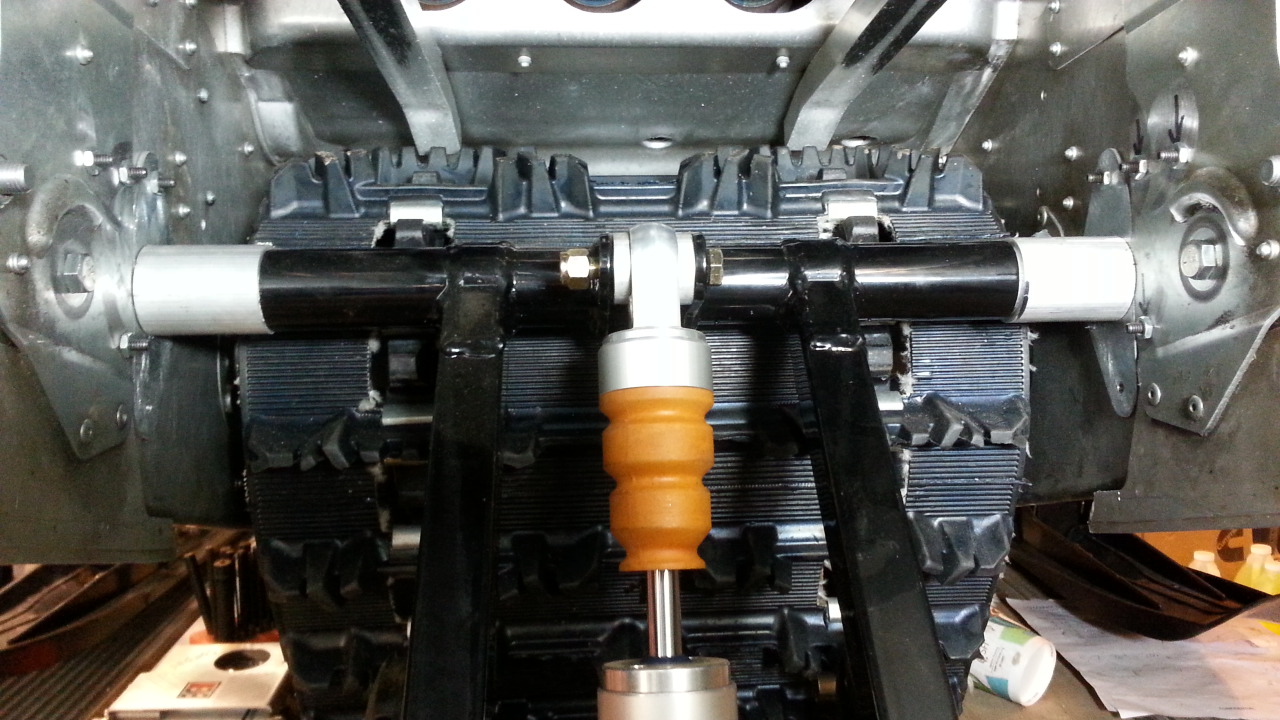

The entire skid is temporarily in place. Everything seems to fit. It's time to change out the track and powder coat the tunnel brackets.

Last edited:

looking good. Swapping the track will be the worst part. The chain case w/reverse was a bear when I did mine. I also had to mount my compressor under the cowl and run air/electric lines. Took a while to get everything sealed up and running well. Been flawless for the last 3 seasons.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

yamahatd said:looking good. Swapping the track will be the worst part. The chain case w/reverse was a bear when I did mine. I also had to mount my compressor under the cowl and run air/electric lines. Took a while to get everything sealed up and running well. Been flawless for the last 3 seasons.

I had a little self education with these when I converted my Vector LTX to a 151. It did get easier after one track change and two gearing changes.

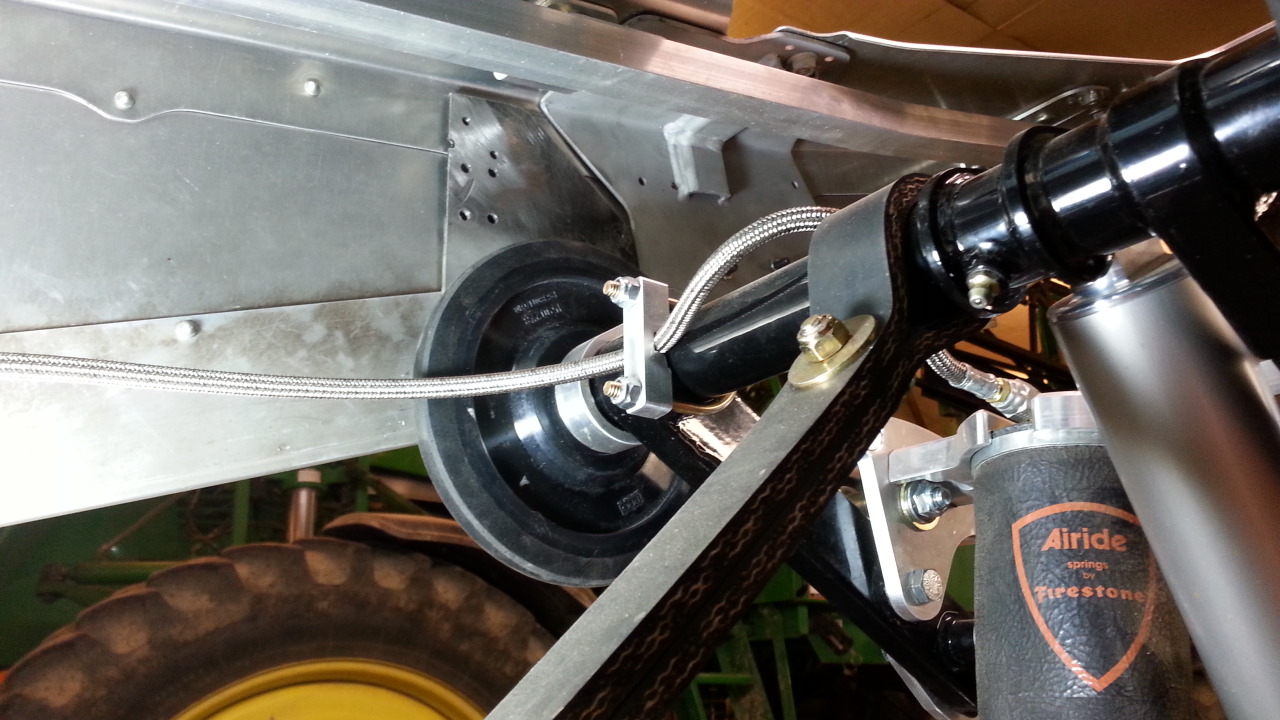

Was your air compressor meant to mount under the cowl? Mine is intended to mount on the rear of the tunnel. There will be no switch or air pressure gage on the handlebar. I'll post pics of that when I get it mounted.

Last edited:

Agreed on the chain case!!!northernsledder.jk said:yamahatd said:looking good. Swapping the track will be the worst part. The chain case w/reverse was a bear when I did mine. I also had to mount my compressor under the cowl and run air/electric lines. Took a while to get everything sealed up and running well. Been flawless for the last 3 seasons.

IMO, Yamaha chain case's (with reverse) are the worse. I had a little self education with these when I converted my Vector LTX to a 151. It did get easier after one track change and two gearing changes.

Was your air compressor meant to mount under the cowl? Mine is intended to mount on the rear of the tunnel. There will be no switch or air pressure gage on the handlebar. I'll post pics of that when I get it mounted.

my M-20 is an older version with the compressor mounted between the brake and oil tank. Mr. Sled has the same set up and I copied his location. I did install some rubber washers to take some of the vibration. The switch and gauge are mounted on the tank cowl. I can adjust while driving though.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I'll have to reach down to my right side and push a button to air up or down. That won't be as convenient as your setup, but it will beat pulling out the Fox hand pump every time I make a change.

yamadog1

TY 4 Stroke Junkie

m-20

in most case's when you find the sweet spot you won't have to change often,

also be sure you have all their extra wheels for your m-20, it'a a must to keep hy-fax

from wearing fast.

i like mine on stiff side i'm 250 and i would keep at 80lbs smooth on trails and good up to 18" bumps after that i go home.

in most case's when you find the sweet spot you won't have to change often,

also be sure you have all their extra wheels for your m-20, it'a a must to keep hy-fax

from wearing fast.

i like mine on stiff side i'm 250 and i would keep at 80lbs smooth on trails and good up to 18" bumps after that i go home.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Re: m-20

Any pointers are appreciated! YAMAHATD also swears by the extra wheels. I plan on ordering a set before the snow flies.

By the way, Naubinway isn't too far away from the Curtis / Germfask area right? Maybe right on highway 2? I rode right through there the first of March. We left the truck in St. Ignace and did a 5 day 1100 mile loop over to the western UP and back. That trip solidified my decision to replace the stock suspension.

yamadog1 said:in most case's when you find the sweet spot you won't have to change often,

also be sure you have all their extra wheels for your m-20, it'a a must to keep hy-fax

from wearing fast.

i like mine on stiff side i'm 250 and i would keep at 80lbs smooth on trails and good up to 18" bumps after that i go home.

Any pointers are appreciated! YAMAHATD also swears by the extra wheels. I plan on ordering a set before the snow flies.

By the way, Naubinway isn't too far away from the Curtis / Germfask area right? Maybe right on highway 2? I rode right through there the first of March. We left the truck in St. Ignace and did a 5 day 1100 mile loop over to the western UP and back. That trip solidified my decision to replace the stock suspension.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I don't know about everyone else, but we are rained out BIG TIME! It will not quit!

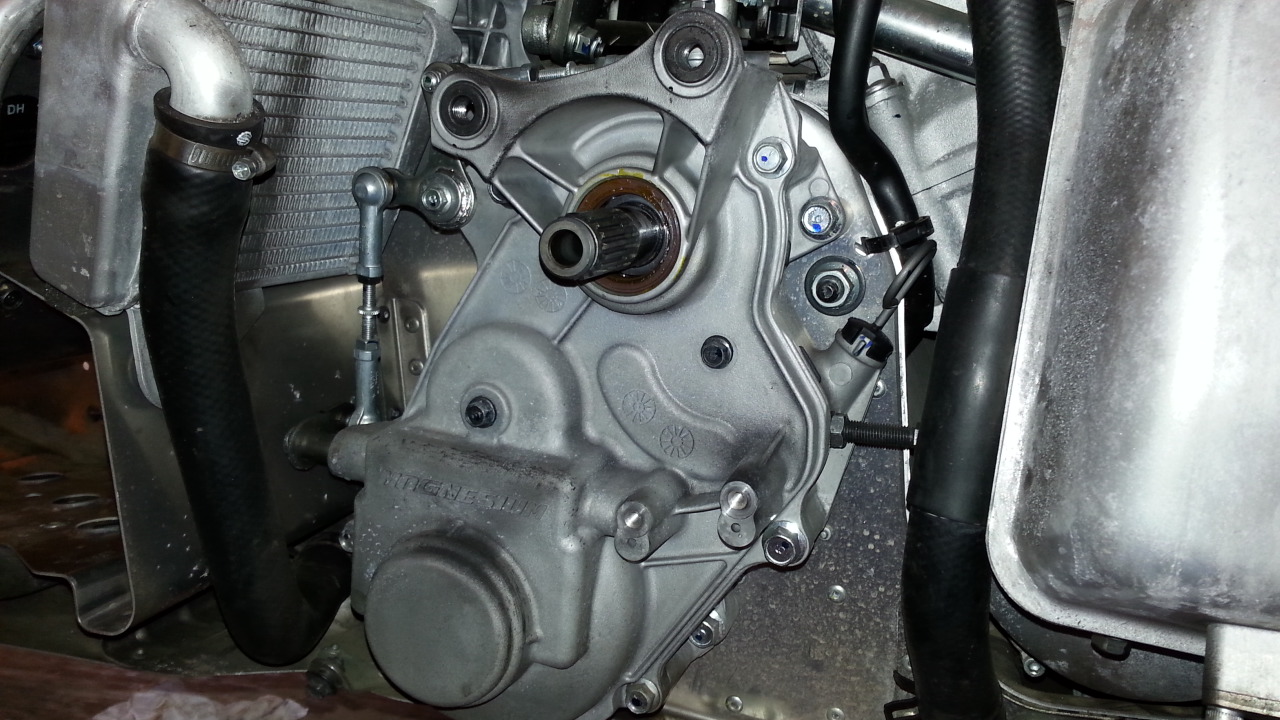

I took apart the chain case, pulled the drive axle and removed the Ripsaw 144. The new Ripsaw II 136 is ready to go in.

I took apart the chain case, pulled the drive axle and removed the Ripsaw 144. The new Ripsaw II 136 is ready to go in.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

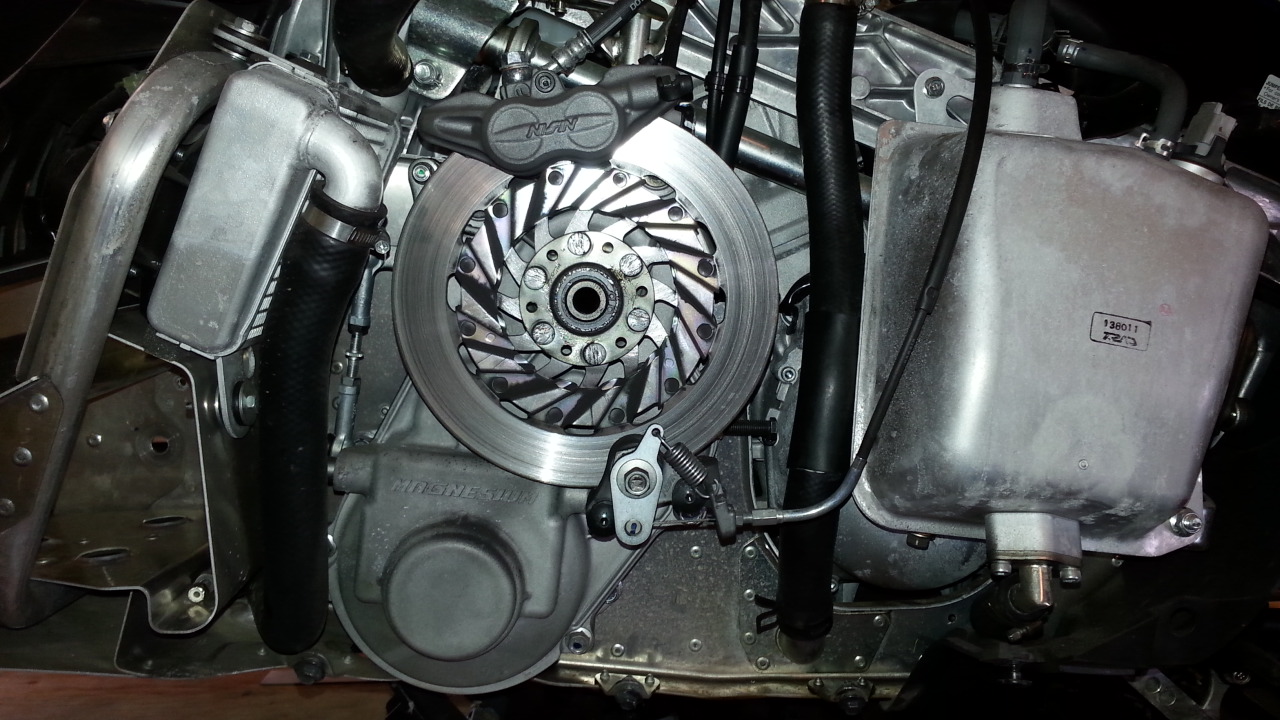

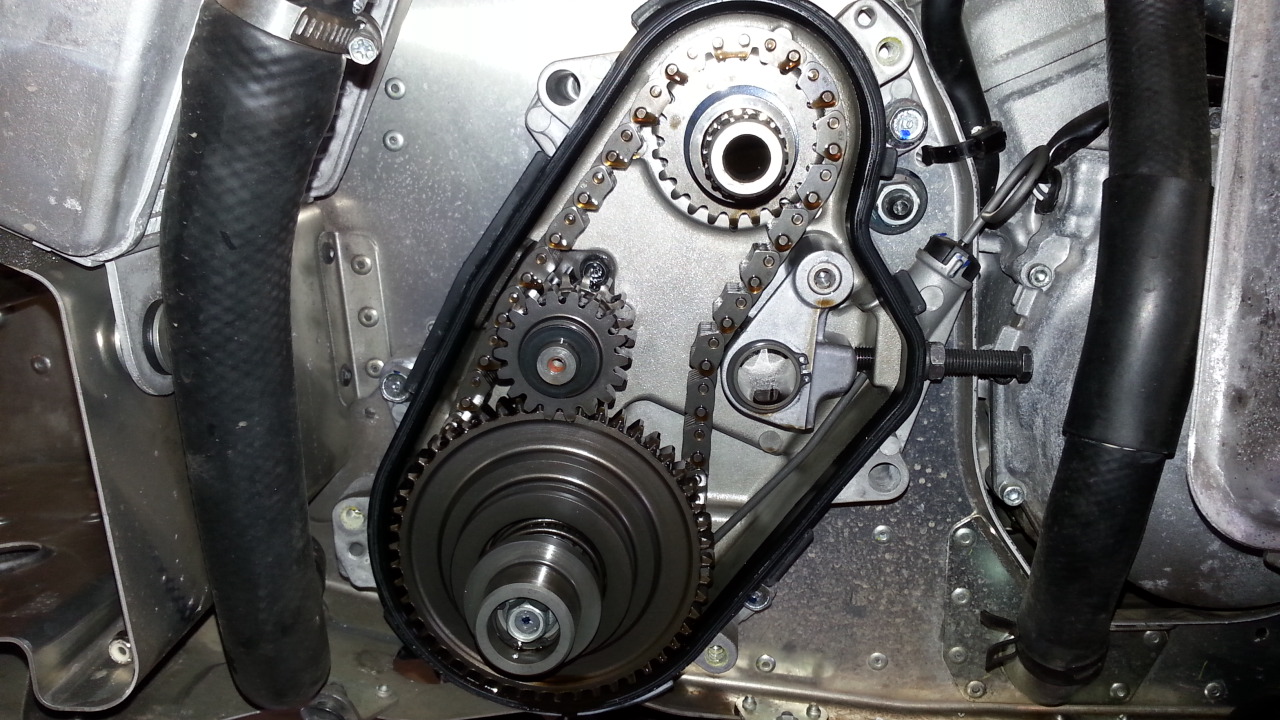

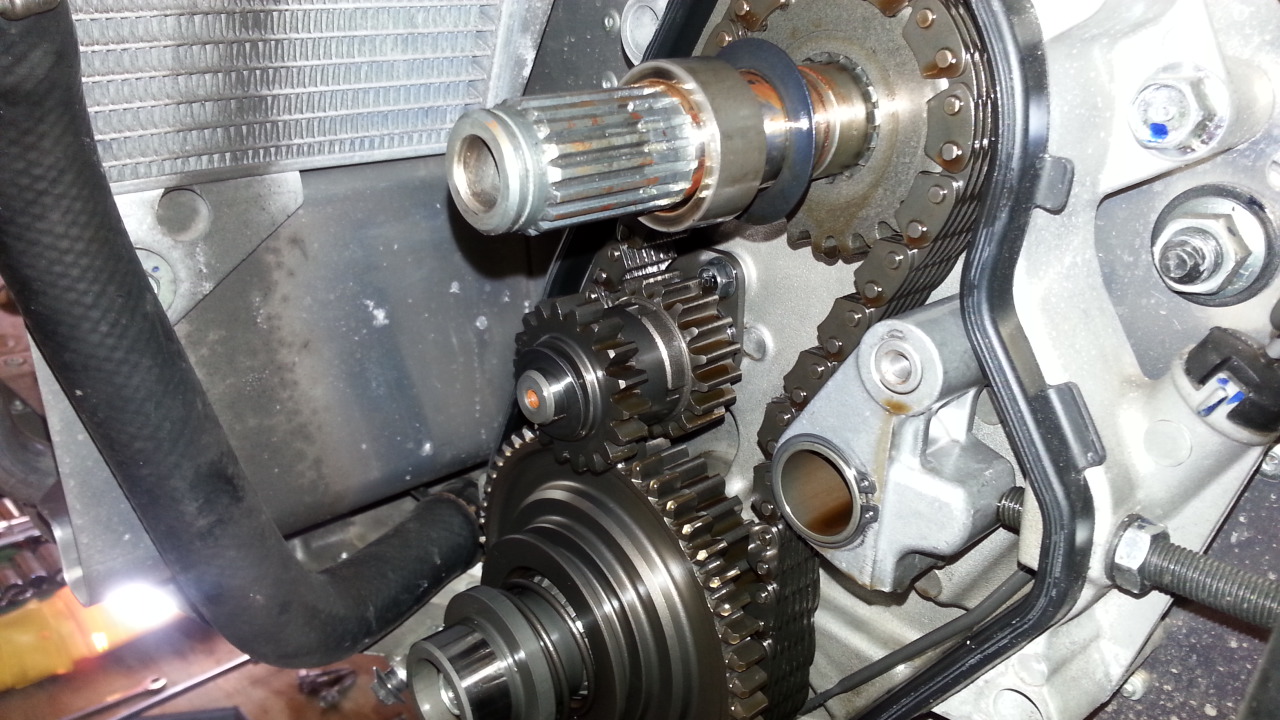

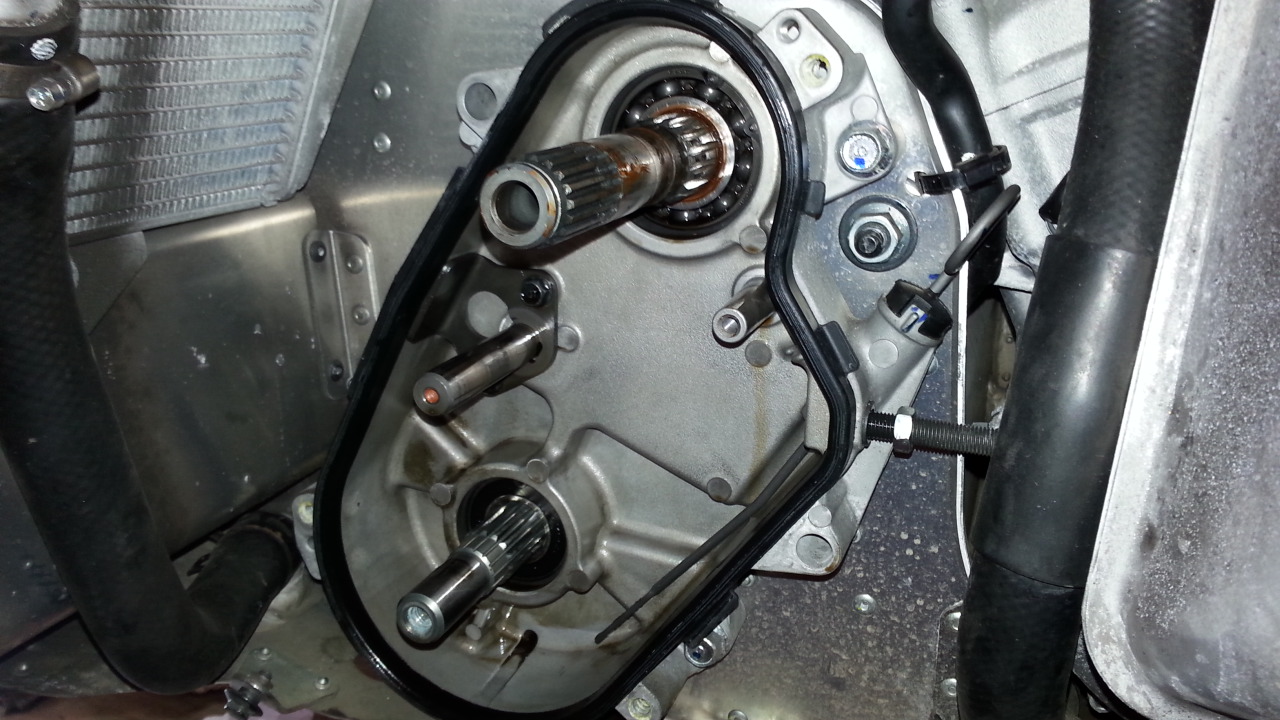

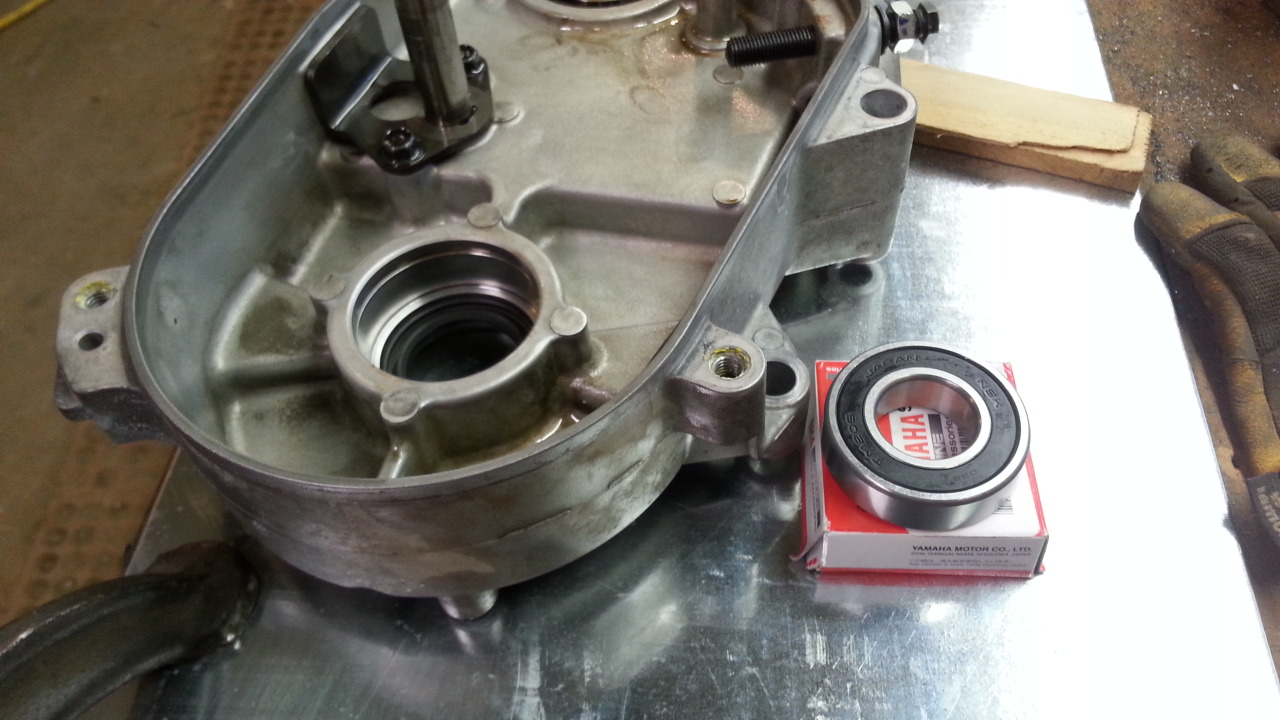

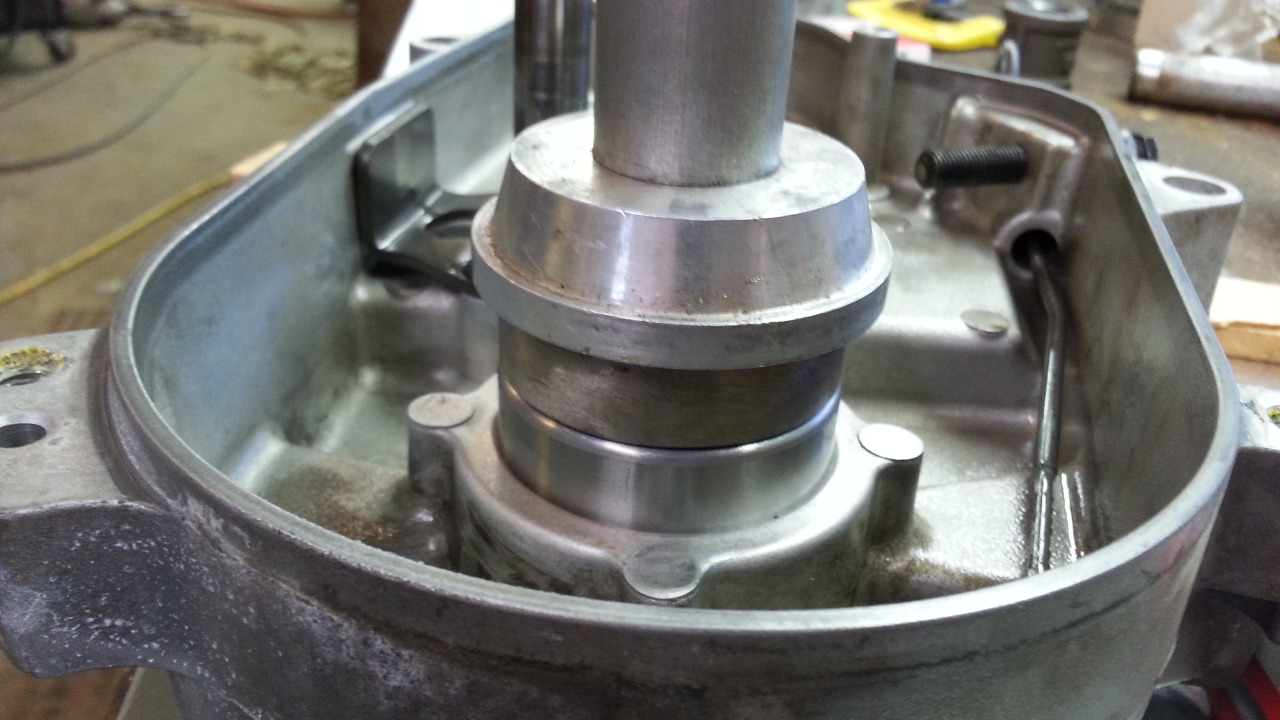

The new track is installed and the chaincase is re-assembled. It probably was not necessary, but I installed new drive axle bearings and seal while I had it apart.

I use an old 6205 outer bearing race for jobs like this; that way I only put pressure on the outer race of the new bearing during assembly. The old bearing race is ground so it will slide into the bore and allow me to drive the new bearing until it bottoms.

Now it's time to powder coat the tunnel brackets and get this skid installed.

I use an old 6205 outer bearing race for jobs like this; that way I only put pressure on the outer race of the new bearing during assembly. The old bearing race is ground so it will slide into the bore and allow me to drive the new bearing until it bottoms.

Now it's time to powder coat the tunnel brackets and get this skid installed.

Last edited:

kviper

VIP Member

It's interesting reading your thread! We have been wet here in central Wisconsin all spring as well and fighting for every acre so in my wait time I did an MCX turbo on my 2012 Apex. Never ready to ride to early! How much do you have to plant yet?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

We have 150 ac of corn and 300 ac of beans left to plant. All the corn that is up is needing sprayed and we just can't get it. We have a winter wheat crop that will be ready to harvest in a month, so I'm hoping we get caught up by then. Building sleds isn't paying as well as farming!

I've never ridden a turbo sled. The Apex is no slouch in stock form. I can only imagine what a turbo or SC would add in performance.

I've never ridden a turbo sled. The Apex is no slouch in stock form. I can only imagine what a turbo or SC would add in performance.

kviper

VIP Member

We have all of our original Field corn acrage planted and only 25 acres of Bean's left to plant but our Wheat crop 135 A did not make it through all the ice this past winter so we collected the Insurance and intended to put corn in but so far it has not gotten dry enough. Other than that we have 300 A sweet corn and 150 Lima bean's to go. Still seeing rain in the forecast as well, gets quite frustrating! Working on the sled helps take your mind off things for a bit but your right it does not pay the bill's. I hate farming for crop insurance! Good luck!

Similar threads

- Replies

- 20

- Views

- 6K

- Replies

- 46

- Views

- 146K

- Replies

- 4

- Views

- 31K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.