CCG71

Newbie

- Joined

- Dec 5, 2021

- Messages

- 6

- Age

- 52

- Location

- Wisconsin

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder R-TX LE

What's the best grease to use for extreme cold?

Confused

Lifetime Member

- Joined

- Oct 12, 2008

- Messages

- 438

- Location

- Mound, MN

- Country

- USA

- Snowmobile

- '21 Sidewinder LTX SE

'24 MXZ 850 Turbo R Comp

'23 MXZ Blizzard 850 ETEC

'24 MXZ Neo+ 600

'88 SnoScoot

This is much like a "what's the best oil" post but I use Amsoil Synthetic Water Resistant Grease in pretty much everything.

CCG71

Newbie

- Joined

- Dec 5, 2021

- Messages

- 6

- Age

- 52

- Location

- Wisconsin

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder R-TX LE

Thank You!

mattison

Veteran

- Joined

- Mar 12, 2019

- Messages

- 40

- Age

- 62

- Location

- RI

- Country

- USA

- Snowmobile

- 2010 RS Vector, 2011 Apex SE, 2016 Apex LE

Lucas Red and Tacky here.

CCG71

Newbie

- Joined

- Dec 5, 2021

- Messages

- 6

- Age

- 52

- Location

- Wisconsin

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder R-TX LE

Thanks, I heard that is a good one.

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 859

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX SE - TD Power Trail, CAI, 3" Super Quiet

2012 RS Vector

2006 Apex GT

- LOCATION

- Middleville, MI

I use this John Deere synthetic grease. It is rated for -45F to 450F.

John Deere Multi-Purpose Extreme Duty Synthetic Gun Grease - TY25744

www.greenpartstore.com

provfisherman

Extreme

- Joined

- Nov 1, 2015

- Messages

- 87

- Location

- Manitoba

- Country

- Canada

- Snowmobile

- 2016 Vector XTX

2015 Venture MP

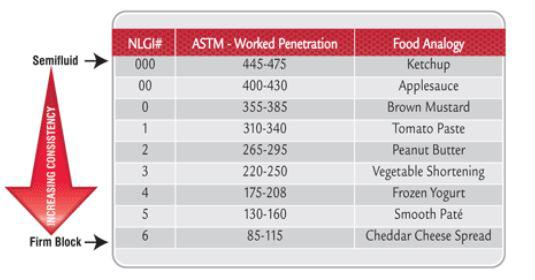

Okay so without getting too technical, you likely want a grease with a NLGI # of 0 and a category rating of GB which has an operating temperature range of -40C to 120C. Not all greases list the category on the labeling, but almost all will list the NLGI #. see if this helps

An NLGI # 0 grease is considered a semmi-fluid grease and has excellent cold pumpability (which is basically it's ability to 'flow' through tubing and hoses etc.) If you have ever seen a backhoe or some other heavy equipment that has an on-board auto greaser in the winter, it is likely using a 0 or 00 grease in that system. So if it can flow through those tiny auto grease lines, it will likely 'flow' within any bearing it is pumped into. Almost all grease manufacturers have such greases in their line-up so brand has little too do with performance in this context.

An NLGI # 0 grease is considered a semmi-fluid grease and has excellent cold pumpability (which is basically it's ability to 'flow' through tubing and hoses etc.) If you have ever seen a backhoe or some other heavy equipment that has an on-board auto greaser in the winter, it is likely using a 0 or 00 grease in that system. So if it can flow through those tiny auto grease lines, it will likely 'flow' within any bearing it is pumped into. Almost all grease manufacturers have such greases in their line-up so brand has little too do with performance in this context.

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 859

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX SE - TD Power Trail, CAI, 3" Super Quiet

2012 RS Vector

2006 Apex GT

- LOCATION

- Middleville, MI

The John Deere synthetic grease that I posted is an NLGI #2 but works for -45F to 450F (-42.7C to 232Okay so without getting too technical, you likely want a grease with a NLGI # of 0 and a category rating of GB which has an operating temperature range of -40C to 120C. Not all greases list the category on the labeling, but almost all will list the NLGI #. see if this helps View attachment 164182

An NLGI # 0 grease is considered a semmi-fluid grease and has excellent cold pumpability (which is basically it's ability to 'flow' through tubing and hoses etc.) If you have ever seen a backhoe or some other heavy equipment that has an on-board auto greaser in the winter, it is likely using a 0 or 00 grease in that system. So if it can flow through those tiny auto grease lines, it will likely 'flow' within any bearing it is pumped into. Almost all grease manufacturers have such greases in their line-up so brand has little too do with performance in this context.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,167

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

Confused

Lifetime Member

- Joined

- Oct 12, 2008

- Messages

- 438

- Location

- Mound, MN

- Country

- USA

- Snowmobile

- '21 Sidewinder LTX SE

'24 MXZ 850 Turbo R Comp

'23 MXZ Blizzard 850 ETEC

'24 MXZ Neo+ 600

'88 SnoScoot

I'll add in my favorite grease dispensing tool.

provfisherman

Extreme

- Joined

- Nov 1, 2015

- Messages

- 87

- Location

- Manitoba

- Country

- Canada

- Snowmobile

- 2016 Vector XTX

2015 Venture MP

Yep, but as you stated, the stuff you reference is synthetic which typically (but not always) performs under extreme (cold/hot) conditions better as the base oil used to make the grease is synthetic. There is no doubt that the use of synthetic oils can be a game changer when used in the proper scenarios, but is not for everything or everybody. If the stuff you use is an NLGI #2 with those operating parameters, just imagine what an NLGI #0 of that brand would have for operating parameters. Also the grease you show here is a category GC-LB which is considered to be of the 'best performance' of the categories, so just like engine oils they have categories. Wheel bearing grease categories are GA, GB, and GC, with the performance and operating parameters of each being better as the last digit increases (A better then B etc). So you got a good one. But even with that a NLGI #2 is still thicker then a NLGI #0.The John Deere synthetic grease that I posted is an NLGI #2 but works for -45F to 450F (-42.7C to 232View attachment 164183C)

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

- Used in a variety of applications with operating temps from -100°F to 500°F

Similar threads

- Replies

- 8

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.