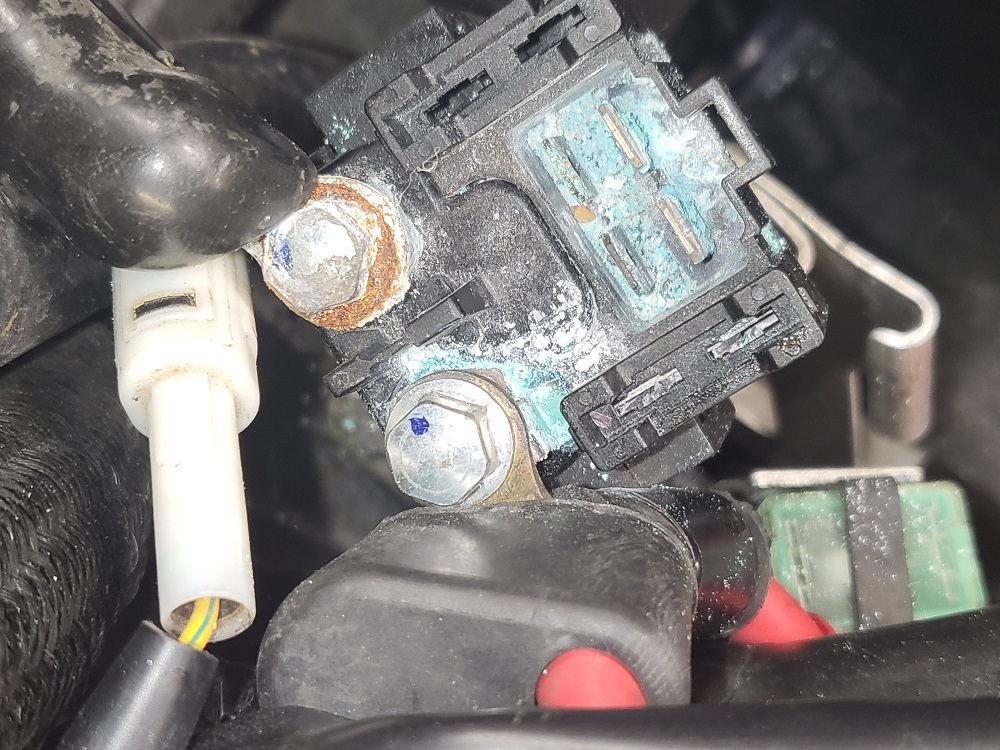

As finish up getting the sled ready for this season I started troubleshooting an intermittent fuel pump. I found the fuse had corroded to the point of losing one leg, and the relay was covered in corrosion as well. This relay was new in 2020. I've seen an unusual amount of corrosion on carbide bolts and the frame which I attribute to a failure to rinse the road salt off after the last time it was trailered. Typically I've seen corrosion on ground connections, but haven't seen it this bad on positive leads. Time to invest in another tube of dielectric grease.

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,944

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

Damn that's ugly. Because these aren't weatherpack type connectors, I usually fill these up with grease, either dielectric or another corrosion preventing type used for trailer wiring.

Don't use Die Electric grease. This insulates the connection and could cause electrical flow issues.

I was a dieheard di-electrical grease guy until one day my truck shut down after I installed a new battery. I greased up the poles and installed the clamps. Made in 20 miles when it shut down. Remove the clamps wiped off the di-electric and away it went. I now use plain old gun grease. Never an issue.

I was a dieheard di-electrical grease guy until one day my truck shut down after I installed a new battery. I greased up the poles and installed the clamps. Made in 20 miles when it shut down. Remove the clamps wiped off the di-electric and away it went. I now use plain old gun grease. Never an issue.

Thanks for the Intel. Wilco.

I wonder what other fubar connections await me.

Dielectric grease is not supposed to be used on the electrical mating surfaces, although typically friction/fit will squeeze out the grease and allow for a good contact. Dielectric grease is supposed to be just a sealant, think of it as a gooey caulk (don't read that out loud) or liquid gasket. @msgt van you should use dielectric grease as it is silicone based and won't rot plastics or rubber. Apply it to the plastic around the connector surfaces, not the electrical contacts. @steiner, when you put it on your battery posts you just got unlucky that it didn't squeeze out, if it had, you would still be a dielectric grease guy  What you should have done is put the clamps on the posts dry and then coat all the exposed surfaces in dielectric grease.

What you should have done is put the clamps on the posts dry and then coat all the exposed surfaces in dielectric grease.

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,944

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

Also had a main ground wire spade connector that greened out like that on my son's Phazer. That I just cut the the whole connector and soldered the wire together. There's also the ignition switch connector that isn't weatherpack that should be checked, cleaned and greased.

This is the stuff I was talking about for greasing connectors. It's not dielectric. However, any grease, including Vaseline, will work to prevent moisture from corroding them.

Yeah, I screwed up on that one. Dielectric actually does mean "does not conduct electricity". Excellent on spark plug wire boots and seals on weatherpack connectors.

This is the stuff I was talking about for greasing connectors. It's not dielectric. However, any grease, including Vaseline, will work to prevent moisture from corroding them.

Yeah, I screwed up on that one. Dielectric actually does mean "does not conduct electricity". Excellent on spark plug wire boots and seals on weatherpack connectors.

Hendo85

Extreme

Is this relay still usable looking like that? Wondering if I need to buy a new one because mines that ugly lolAs finish up getting the sled ready for this season I started troubleshooting an intermittent fuel pump. I found the fuse had corroded to the point of losing one leg, and the relay was covered in corrosion as well. This relay was new in 2020. I've seen an unusual amount of corrosion on carbide bolts and the frame which I attribute to a failure to rinse the road salt off after the last time it was trailered. Typically I've seen corrosion on ground connections, but haven't seen it this bad on positive leads. Time to invest in another tube of dielectric grease.View attachment 164862View attachment 164863

I'd replace it!Is this relay still usable looking like that? Wondering if I need to buy a new one because mines that ugly lol

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 14

- Views

- 2K

- Replies

- 5

- Views

- 945

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.