KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,674

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

All that matters here is that the bearing is normalized and sitting straight on the shaft and the shaft isn't bent. If the bearing is crooked on the shaft, its going to wobble. Nothing more, nothing less.

If the shaft tolerance was tight on the bearing, and the shaft is straight, there would be no wobble. Period. Has nothing to do with how the tunnel is built or out of whack. It only has to do with how straight the bearing is sitting on the shaft.

If the shaft tolerance was tight on the bearing, and the shaft is straight, there would be no wobble. Period. Has nothing to do with how the tunnel is built or out of whack. It only has to do with how straight the bearing is sitting on the shaft.

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

Just an FYI concerning what caused the caliper wobble. Loctite. Too much on too many components! But

primarily some got outback of the bearing I was told. It now runs straight and true!

primarily some got outback of the bearing I was told. It now runs straight and true!

vodoo child

Expert

- Joined

- Oct 29, 2005

- Messages

- 464

- Location

- Palmerton Pa.

- Country

- USA

- Snowmobile

- 2018 Sidewinder LTX/LE 50th

I'll ad my 2 cents. My experience 2 years ago was. Tore apart the brake and bearing , my drive shaft to inner race was .015 thousands. So I tried the dimple method and green loc tite. Let set up over night. Checked next day by running on the stand, tunnel and brake looked to be breathing!  Tore back apart and had to split caliper to pull off bearing! Bit the bullet and ordered the BOP wedge from Travis and complete driveshaft assembly and bearing from Partzilla! Bench tested the wedge at 20 ft lbs. bearing didn't budge. Reassembled and set wedge at 40 ft lbs. 4'500+ miles and zero issues with the disc brake or chain case since!

Tore back apart and had to split caliper to pull off bearing! Bit the bullet and ordered the BOP wedge from Travis and complete driveshaft assembly and bearing from Partzilla! Bench tested the wedge at 20 ft lbs. bearing didn't budge. Reassembled and set wedge at 40 ft lbs. 4'500+ miles and zero issues with the disc brake or chain case since!

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 447

- Age

- 60

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

I did the EXACT same as this last year at 1000klm when i put storm on... dimpled/knurled and locktite, then assembled, ballooned track off the driver and spun it before tightening all the bolts to make sure it spun square, WORKED PERFECT ... then as a precaution 2 days ago i put the precision efi shaft saver in... had to hammer the hell out of it to get in... was a little worried about that as i didnt know if hammering shaft would shift it towards chain case... i couldnt find my brake caliper hone to use inside the shaft.... i think the dimpling may have made it a little tighter in there... SO yesterday i also took caliper appart and pulled pistons out and cleaned with 400 emery cloth and changed brake fluid to racing silicone purple fluid... i had noticed my ultra light drilled rotor from Black Diamond had basically ate my ceramic pads, soo i put the fact pads back in put it all back and started and shaft runs perfectly true. THEN, being home alone and bored.... just to be sure pulled chain case off and checked everything and was able to put in the PREVOST RACING bushing (that ive had for a month), on the lightened 25 top gear i got from Scott Taylor, checked tensioner roller and everything was awesome!! refilled with Amsoil synthetic racing chain/gear oil and all readdy to go to TURBO DYNAMICS on Tuesday for injectors and Mod Stock Ported Turbo upgrade!!! does it ever stop... lol i think i need to get rid of this testosterone.. lolI'll ad my 2 cents. My experience 2 years ago was. Tore apart the brake and bearing , my drive shaft to inner race was .015 thousands. So I tried the dimple method and green loc tite. Let set up over night. Checked next day by running on the stand, tunnel and brake looked to be breathing!Tore back apart and had to split caliper to pull off bearing! Bit the bullet and ordered the BOP wedge from Travis and complete driveshaft assembly and bearing from Partzilla! Bench tested the wedge at 20 ft lbs. bearing didn't budge. Reassembled and set wedge at 40 ft lbs. 4'500+ miles and zero issues with the disc brake or chain case since!

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

During my fall maintenance the driveshaft, bearing and brake disc were replaced and torqued down the wedge.

Once I finished all my maintenance and fired up sled I too had my caliper moving in and out and my tunnel.

Loosened up my wedge and ran sled on stand.

It took at least 4 to 5 blasts with the throttle for bearing to settle in with zero wobble.

Retorqued wedge and all is good.

THIS IS WITH BRAND NEW PARTS!

Once I finished all my maintenance and fired up sled I too had my caliper moving in and out and my tunnel.

Loosened up my wedge and ran sled on stand.

It took at least 4 to 5 blasts with the throttle for bearing to settle in with zero wobble.

Retorqued wedge and all is good.

THIS IS WITH BRAND NEW PARTS!

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 967

- Age

- 56

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

I checked mine couple years ago when installing the bop wedge and i wasn't movingIs it normal for the caliper and rotor to move 1/8-1/4” as the track is spinning. I checked mine for a reason and expected the tunnel to be perfectly still where the caliper bolts thru it, but it is not!

While idling and rear is lifted off the ground to permit track to spin, I see in and out movement on my caliper, rotor and the guard that is bolted to the caliper!

Should it be perfectly still as the cog shaft rotates or is some tunnel flex normal?

Gman25

Extreme

- Joined

- Dec 11, 2019

- Messages

- 56

- Age

- 55

- Location

- ottawa

- Country

- Canada

- Snowmobile

- 2018 sidewinder ltx

1999 srx 70

1993 vmax 750

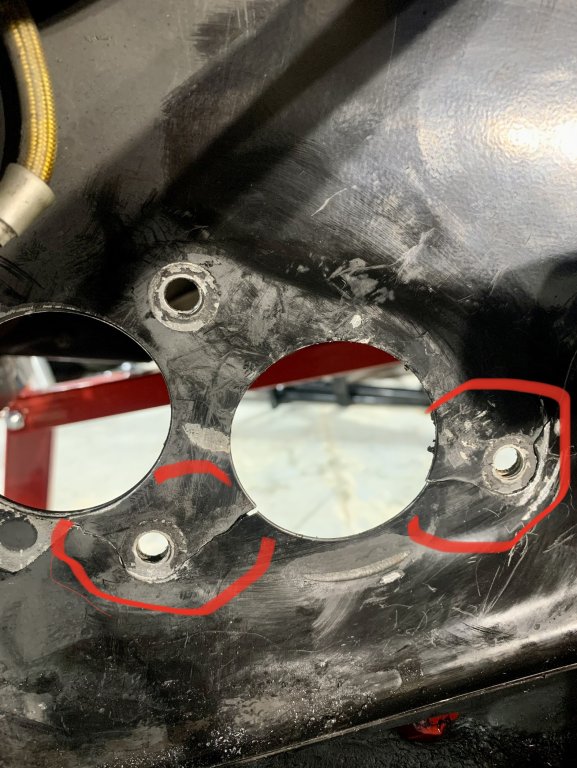

Mine was doing same thing i had shaft saver and new brg installed 2500 km prior here is what mine looked like on disassembly

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Are the holes egged out? Can’t tell by the photo

Ms

Ms

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,674

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Are the holes egged out? Can’t tell by the photo

Ms

The tunnel is cracked because whoever put the BOP wedge in did not normalize the bearing onto the shaft. The shaft needs rotated as it’s getting tighten down and torqued up. If you don’t do this, the bearing gets cocked on the shaft and tighten down crooked, so the caliper wobbles and breaks/cracks the chassis.

I go so far as to put a dial indicator on the caliper to make sure everything is perfect, and true, so no wobble occurs.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Not cool.

I know about this problem all too well.

A few years back on an early ride my brake was pulsing???. Pull the cowl off and watched the rotar- yikes. It was wobbling.

Had to tear it all apart again and get to the bottom of it. In my case- I had green loctited it together and didn’t realize the two surfaces did not mate ‘true’ until the first ride.

Ms

I know about this problem all too well.

A few years back on an early ride my brake was pulsing???. Pull the cowl off and watched the rotar- yikes. It was wobbling.

Had to tear it all apart again and get to the bottom of it. In my case- I had green loctited it together and didn’t realize the two surfaces did not mate ‘true’ until the first ride.

Ms

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Insurance cover this?

Similar threads

- Replies

- 41

- Views

- 4K

- Replies

- 7

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.