I can create a quick pattern tomorrow with the inner most 3" being avoided. Thanks

SideHogger

TY 4 Stroke Guru

- Joined

- Apr 16, 2016

- Messages

- 939

- Age

- 54

- Location

- upstate ny

- Country

- USA

- Snowmobile

- 2017 Ltx-Le Sidewinder

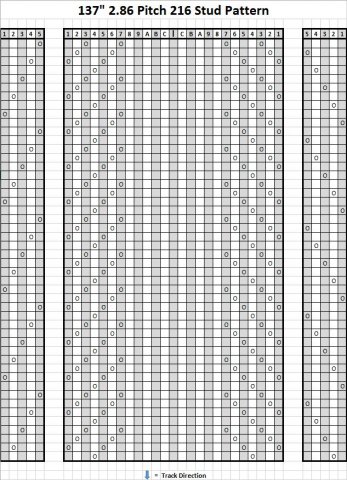

Sorry, but how is this pattern not avoiding middle 2-3" of track? I dont get it.I just quickly came up with this pattern which avoids the center 2" of the track. You can use this in combination with our studding template. It has 144 studs down the center and 48 on the outside for a 137" long track. A similar design can be used/created for a 129" track.

View attachment 122432

So 135 1.325 studs on a 129" track has the potential to cause an issue?

3 studs per bar

3 studs per bar

Sorry, but how is this pattern not avoiding middle 2-3" of track? I dont get it.

When utilizing the black template shown in the image above, you just follow the design shown below. This design shows a studding pattern with 112 studs on the inside and 48 on the outside. The one shown below will avoid studding within the center 3" of the track.

This pattern shows 168 studs on the inside belt and 48 on the outside for 216. The template itself is universal and countless stud patterns can be created from it. Each row represents a lug spacing on your track (48 in total on a 137") Hopefully this clears it up.

So 135 1.325 studs on a 129" track has the potential to cause an issue?

3 studs per bar

I believe it will NOT be an issue based on 1.325 - 1.00" lug (net minus mat thickness) = .325 over the lug ( based on how woodys measures) and from reports you have a max of .630 however each stud maker measures differently...

the safest way is to take the stud...lay a backer on it bottomed out o the shoulder (doesnt apply to shoulderless studs) and measure the net protrusion...

then lay a straight edge across your lugs...measure from the bottom of the straight edge to the track mat...the difference between the two is your protrusion.

With a properly installed 1.325" woody's stud on a 1.25" lug track, you will get ~.375" over the lug. A properly installed 1.450" woody's stud on a 1.25" lug track will put you at ~.500" over the lug. I have used calipers for this measurement because I have OCD, haha. Below is a woody's chart explaining stud length.

http://assets1.mytrainsite.com/501450/g1-06-0001_woodys_penetration_chart_inches-mm_rev052516.pdf

http://assets1.mytrainsite.com/501450/g1-06-0001_woodys_penetration_chart_inches-mm_rev052516.pdf

Snowaddict

TY 4 Stroke Master

- Joined

- Feb 28, 2005

- Messages

- 1,107

- Location

- Menasha, WI

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX-LE

- mstahl88

So, from what I am reading a 1.325 stud on a 1.25 track should be ok? I still am considering 144 down the middle on a 137 LTX-LE. I know not up to snuff for SJWith a properly installed 1.325" woody's stud on a 1.25" lug track, you will get ~.375" over the lug. A properly installed 1.450" woody's stud on a 1.25" lug track will put you at ~.500" over the lug. I have used calipers for this measurement because I have OCD, haha. Below is a woody's chart explaining stud length.

http://assets1.mytrainsite.com/501450/g1-06-0001_woodys_penetration_chart_inches-mm_rev052516.pdf

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

I will stick with the 1.325 that I have always ran. And yes its certainly not the most aggressive length I get that for sure. And REMEMBER you will avoid any issues if you stay out of the 1.5 inches in the very center. Could a guy just run some shorter ones in the very middle , and stay long elsewhere?

Last edited:

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

You wont be disappointed going outside> I had a really hard time doing a few years ago. But this sled has some serious HP, and if you stay 1.325 outside its even less risk IMHOSo, from what I am reading a 1.325 stud on a 1.25 track should be ok? I still am considering 144 down the middle on a 137 LTX-LE. I know not up to snuff for SJ, but just really don't want to go on the outside. 90% of my riding is groomed trail with an occasional frozen lake if the trail goes across it.

monte1214

TY 4 Stroke Guru

- Joined

- Apr 20, 2005

- Messages

- 752

- Location

- Durham Region, ON

- Website

- www.portperrysnowmobileclub.com

- Country

- Canada

- Snowmobile

- 2017 Sidewinder LTX-SE

Ok....so do I need tunnel protectors or not?

137 and putting 144 up the middle.

137 and putting 144 up the middle.

bruce...left you a message and I have people contacting you now for templates....make sure you save me one lol

based on .500" net over the lug and the measurements provided of .630" differential on a 1.450" you have .130" or 1/8" space to play with ...could it work...yes...but a thin margin for error...

if your track isnt tight or if you grab a handful of brakes etc.....this is my concern...

1.325"s give you another 1/8" ...so now you are at 1/4"...still not warm and fuzzy...but getting better...but that only gives .375 or 3/8" inch of protrusion over the lug ...

personally Id rather have more traction in the safer place and not risk is with any stud...

to not stud outside with this much power IMHO is a waste...but if you go outside..IMHO every bar gets them...they are tightened to max spec and get blue thread locker...theirs strength in numbers so Im not concerned...better than shredding the tunnel on my new machine IMHO

you will need the heat exchanger protectors regardless of your choice ...and to bottom line it...depending on factors...especially balloning which is incresed when you stud middle only.....if you stud middle only...even with the 1.325's...there's a chance you could hit the tunnel there.

based on .500" net over the lug and the measurements provided of .630" differential on a 1.450" you have .130" or 1/8" space to play with ...could it work...yes...but a thin margin for error...

if your track isnt tight or if you grab a handful of brakes etc.....this is my concern...

1.325"s give you another 1/8" ...so now you are at 1/4"...still not warm and fuzzy...but getting better...but that only gives .375 or 3/8" inch of protrusion over the lug ...

personally Id rather have more traction in the safer place and not risk is with any stud...

to not stud outside with this much power IMHO is a waste...but if you go outside..IMHO every bar gets them...they are tightened to max spec and get blue thread locker...theirs strength in numbers so Im not concerned...better than shredding the tunnel on my new machine IMHO

you will need the heat exchanger protectors regardless of your choice ...and to bottom line it...depending on factors...especially balloning which is incresed when you stud middle only.....if you stud middle only...even with the 1.325's...there's a chance you could hit the tunnel there.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Yes you need them. They are more for the rear of the tunnel.Ok....so do I need tunnel protectors or not?

137 and putting 144 up the middle.

The clearance issue is in the front

uprider800

Expert

- Joined

- Mar 18, 2016

- Messages

- 262

- Age

- 15

- Location

- winneconne wi

- Country

- USA

- Snowmobile

- Arctic Cat xf 9000

So if I'm reading this right and I have a 1.50 fast trac stud I need to stay out of the center 3 in correct? Also for the guy making templates will you be making a pattern for the 129 s 180 studs using the outside and staying out of the center 3 in?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

you are correct (we feel so far)

he makes a template...you make your own pattern..he's merely showing the possibilities..

he makes a template...you make your own pattern..he's merely showing the possibilities..

Similar threads

- Replies

- 4

- Views

- 879

- Replies

- 1

- Views

- 695

- Replies

- 27

- Views

- 4K

- Replies

- 4

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.