Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Pictures worth a thousand words - nice job.

If you every find yourself cutting a new one, I would be more than happy to purchase one from you.

Was thinking about doing something similar but not as detailed, or as large. You obviously have the equipment to make this happen.

Thanks for sharing.

MS

If you every find yourself cutting a new one, I would be more than happy to purchase one from you.

Was thinking about doing something similar but not as detailed, or as large. You obviously have the equipment to make this happen.

Thanks for sharing.

MS

RX1Jim

TY 4 Stroke Junkie

Craigwsrx,

Nice job!!! What thickness metal did you use? I made a similar plate which mounts on the bottom side of the tunnel. I incorporated the hose protectors in the plate. It was a royal pain to mock up and build. When I take the rear skid out for servicing, I'll post a few photos. I thought of mounting the plate on top of the tunnel as you did, just did not want to have to do a lot of disassembly . If the workload in my shop ever slows down, I'll stack a few plates to gang mill them for members of this site (When and IF the workload slows down). Do you have a CAD file of the plate that you would be willing to share?

I've made a number of other improvements to the sled such as all the steel on steel bushings sets in the rear skid and front suspension with stainless steel and oil-lite bushings, replaced the lightweight ultra weak front rear skid suspension bar with a 3/4" dia stainless steel shaft, replace the unpainted, unplated bare steel collars and sleeves in the rear skid with stainless steel parts (I HATE RUST!!!!)

Jim

Nice job!!! What thickness metal did you use? I made a similar plate which mounts on the bottom side of the tunnel. I incorporated the hose protectors in the plate. It was a royal pain to mock up and build. When I take the rear skid out for servicing, I'll post a few photos. I thought of mounting the plate on top of the tunnel as you did, just did not want to have to do a lot of disassembly . If the workload in my shop ever slows down, I'll stack a few plates to gang mill them for members of this site (When and IF the workload slows down). Do you have a CAD file of the plate that you would be willing to share?

I've made a number of other improvements to the sled such as all the steel on steel bushings sets in the rear skid and front suspension with stainless steel and oil-lite bushings, replaced the lightweight ultra weak front rear skid suspension bar with a 3/4" dia stainless steel shaft, replace the unpainted, unplated bare steel collars and sleeves in the rear skid with stainless steel parts (I HATE RUST!!!!)

Jim

02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 580

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

You could probably have a few customers with that list of "upgrades"Craigwsrx,

Nice job!!! What thickness metal did you use? I made a similar plate which mounts on the bottom side of the tunnel. I incorporated the hose protectors in the plate. It was a royal pain to mock up and build. When I take the rear skid out for servicing, I'll post a few photos. I thought of mounting the plate on top of the tunnel as you did, just did not want to have to do a lot of disassembly . If the workload in my shop ever slows down, I'll stack a few plates to gang mill them for members of this site (When and IF the workload slows down). Do you have a CAD file of the plate that you would be willing to share?

I've made a number of other improvements to the sled such as all the steel on steel bushings sets in the rear skid and front suspension with stainless steel and oil-lite bushings, replaced the lightweight ultra weak front rear skid suspension bar with a 3/4" dia stainless steel shaft, replace the unpainted, unplated bare steel collars and sleeves in the rear skid with stainless steel parts (I HATE RUST!!!!)

Jim

craigwsrx

Lifetime Member

- Joined

- Feb 19, 2007

- Messages

- 139

- Location

- Fenton Mi.

- Country

- USA

- Snowmobile

- 2017 Sidewinder 27,000 miles

2009 Nytro xtx 31,000 miles

2006 Attak 26,500 miles

2003 RX1 13,500 miles

2000 Mountain Max 14,000 miles

1998 SRX Mountain 17,000 miles

1995 V Max 600

1979 SRX 440

1975 GPX 338

1973 GP 338

I designed it and had them made at a shop with CNC machines. I do have 15 extra I made, and will sell. I do have a shop and do some work on sleds for people who know of me. I try not to be to busy because as you can see by my mileage I like to ride and ride as much as I can. I'm in the UP of Michigan riding this weekend, nothing better than spring riding.I will sell them, not sure how to do this as I am not a vendor and don't want to break any Totallyamaha rules. I will sign up to be a vendor so I can forward my contact info for anyone wanting one of these tunnel plates. You do need to drill holes in plate for rivets, it is critical to line up along front edge to match to heat exchanger. Plate is about 1/6" thick stainless steel, I can check exact thickness when I get back to my shop on Monday. It does make the job easier to have a drill press to use for drilling stainless for rivets. This is a major modification so be prepared for removing gas tank, exhaust header, etc to preform install. I have been involved with all of installs thru my shop of 8 sleds, most with no damage to tunnel and didn't want any issues like I had. Price for plate and 14 rivets is $50 plus shipping.

Awesome job! But why not a plate on the bottom side of the tunnel so you don't have to do major disassembly?

I would prob be interested in a tunnel reinforcement plate installed in the tunnel.

I would prob be interested in a tunnel reinforcement plate installed in the tunnel.

craigwsrx

Lifetime Member

- Joined

- Feb 19, 2007

- Messages

- 139

- Location

- Fenton Mi.

- Country

- USA

- Snowmobile

- 2017 Sidewinder 27,000 miles

2009 Nytro xtx 31,000 miles

2006 Attak 26,500 miles

2003 RX1 13,500 miles

2000 Mountain Max 14,000 miles

1998 SRX Mountain 17,000 miles

1995 V Max 600

1979 SRX 440

1975 GPX 338

1973 GP 338

You could if you designed it that way. I did mine from the top because an ice chunk got jammed up in top of tunnel and pushed tunnel up and took out my heatexchanger

hose.I did mine from the top to tie it into front motor mount/sub frame with new rivets. Not sure from underside to design around heatexchangers etc. Lots of 0ptions , all good that works.

hose.I did mine from the top to tie it into front motor mount/sub frame with new rivets. Not sure from underside to design around heatexchangers etc. Lots of 0ptions , all good that works.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I designed it and had them made at a shop with CNC machines. I do have 15 extra I made, and will sell. I do have a shop and do some work on sleds for people who know of me. I try not to be to busy because as you can see by my mileage I like to ride and ride as much as I can. I'm in the UP of Michigan riding this weekend, nothing better than spring riding.I will sell them, not sure how to do this as I am not a vendor and don't want to break any Totallyamaha rules. I will sign up to be a vendor so I can forward my contact info for anyone wanting one of these tunnel plates. You do need to drill holes in plate for rivets, it is critical to line up along front edge to match to heat exchanger. Plate is about 1/6" thick stainless steel, I can check exact thickness when I get back to my shop on Monday. It does make the job easier to have a drill press to use for drilling stainless for rivets. This is a major modification so be prepared for removing gas tank, exhaust header, etc to preform install. I have been involved with all of installs thru my shop of 8 sleds, most with no damage to tunnel and didn't want any issues like I had. Price for plate and 14 rivets is $50 plus shipping.

I'll take one of your plates sir!

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Snow pushed tunnel up and now enters the engine compartment over the top of the heat exchanger. Gets snow on belt from here.

Tunnel is only .050" thick.

Last edited:

Wow that sucks. You going to use that plate you asked for and make another strip for under tunnel? Fine thread Button head allen bolts would sandwich it tighter than those rivets ever will also.

Last edited:

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Yes. I'll take some pics of the repair and post up on here after I am finished.

Sucks Buddy. You will make it better and stronger though.Yes. I'll take some pics of the repair and post up on here after I am finished.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Yep, I am in deep doing some preventive maintenance!

SaskAttack

Expert

- Joined

- Jan 4, 2006

- Messages

- 304

- Location

- Corning,SK.

- Country

- Canada

- Snowmobile

- 17 Sidewinder XTX-SE

- LOCATION

- Corning, SK. Canada

Heavy duty plate not a bad idea, hard running on -32 day on hard packed icy trail. Shelter was about 30 K from home and sled was fairly clean of snow at shelter, knocked one side clean and thought should take a picture before I clean it right off, that is ice although it looks like snow. All sleds had same problem.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

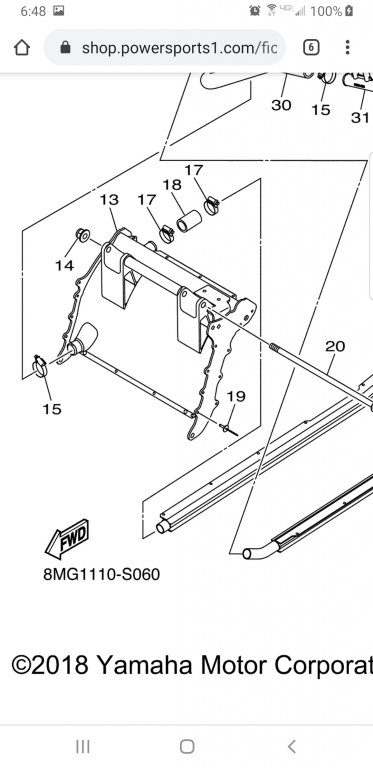

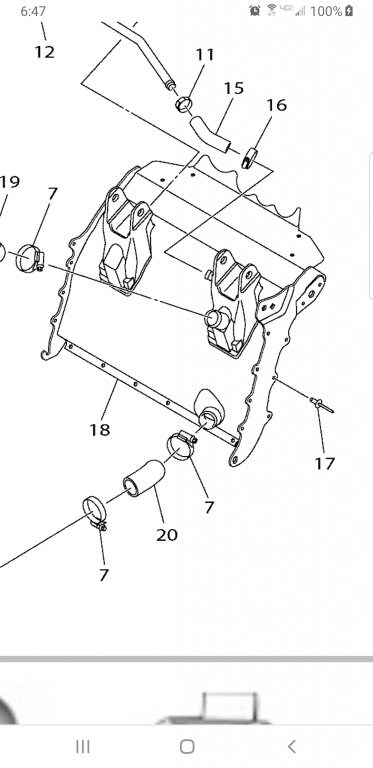

Looks like a completely different design fwd heat exchanger on the viper than the sidewinder. Viper has no rear exchanger.

First picture is sidewinder heat exchanger.

Second pic is viper.

First picture is sidewinder heat exchanger.

Second pic is viper.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

Heavy duty plate not a bad idea, hard running on -32 day on hard packed icy trail. Shelter was about 30 K from home and sled was fairly clean of snow at shelter, knocked one side clean and thought should take a picture before I clean it right off, that is ice although it looks like snow. All sleds had same problem.

That's gonna hurt.....lol

Guys that spout "the new yamis don't ice like the old ones" clearly have never been out in cold weather. They all ice bad beyond -20. At -30 it doesn't get better..... Nice pic. Thanks for sharing.

MS

Similar threads

- Replies

- 21

- Views

- 33K

- Replies

- 29

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.