It shouldn't lose any travel. If the bump stop is compressing enough that the shock is hitting, the travel was never there. The bump stops probably only need to be raised 1/8" or so to stop the impact.

Vs grinding the tube it would lose travel. Bumpstop compression is part of travel. Nothing should hit even with bumpstops completely removed. At least that’s how a proper suspension is designed.It shouldn't lose any travel. If the bump stop is compressing enough that the shock is hitting, the travel was never there. The bump stops probably only need to be raised 1/8" or so to stop the impact.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,050

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

The rubber bump stops on the rail have hardly any damage on them.It shouldn't lose any travel. If the bump stop is compressing enough that the shock is hitting, the travel was never there. The bump stops probably only need to be raised 1/8" or so to stop the impact.

Pi$$ poor design when the shock is hitting another component while going thru travel.

I go 220 lbs. Rear springs set on medium and compression setting on 2 or 3 depending on trail conditions. One of these cracked shocks came off my sled.

I ground that arm down when I made this post back in 2019.

Shock was serviced one year ago and was fine at that time. This past winter it had started to leak and I didnt notice it until doing preseason maintenance this fall.

The crack may have been there and not leaked fluid due to the amount of green loctite on it.

I sure am happy Cannondale27 found the crack before I found it on the trail in pieces.

hellflyer

TY 4 Stroke Master

- Joined

- Dec 2, 2008

- Messages

- 1,086

- Location

- Georgtown ONT. Canada

- Country

- Canada

- Snowmobile

- 2020 sidewinder ltx se

Do you think it could be related to transfer block removal? My 2020 has no issues and I blew the crap out of my bottoming bumpers the first year until I revalved the shock and replaced them. I kept my transfer blocks in place. Just might change the geometry that little bit.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,050

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

The qs3 shock end with reservoir should have an angle on it away from the crossshaft to clear it.

A shock with no rezzy would have no issues here.

A shock with no rezzy would have no issues here.

hellflyer

TY 4 Stroke Master

- Joined

- Dec 2, 2008

- Messages

- 1,086

- Location

- Georgtown ONT. Canada

- Country

- Canada

- Snowmobile

- 2020 sidewinder ltx se

I just had my qs3 out 2 days ago to change oil and inspect and with 6000km and my 280lbs it hasn't made contact!

Turboflash

TY 4 Stroke God

- Joined

- Mar 18, 2019

- Messages

- 2,446

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

All depends on where springs and damping are set, how much rider weighs, how big a bump you hit at what speed.

Never be an issue on smooth well-groomed flat trails. If you ride in the ditch or on rough stuff, or like to fly sled off ground, it could be an issue.

Never be an issue on smooth well-groomed flat trails. If you ride in the ditch or on rough stuff, or like to fly sled off ground, it could be an issue.

hellflyer

TY 4 Stroke Master

- Joined

- Dec 2, 2008

- Messages

- 1,086

- Location

- Georgtown ONT. Canada

- Country

- Canada

- Snowmobile

- 2020 sidewinder ltx se

Like I said I destroyed my bump stops the first year and no contact but the geometry changed a bit with the 19'-20's so it may not happen with the newer ones?

Right. Even a bolt hole in a slightly off position changes geometry at shock alot. I will say this though. I do alot of these shocks and see the witness mark on almost every one of them. It never was a issue till this year for me when I got two in a row in 2 weeks time. Now me being a suspension guy I could not ride without doing something about it. I believe I told people about the mark years ago. There are standards for clearance and the standards have not been met. I would deal with it or risk a possibly season ending failure.All depends on where springs and damping are set, how much rider weighs, how big a bump you hit at what speed.

Never be an issue on smooth well-groomed flat trails. If you ride in the ditch or on rough stuff, or like to fly sled off ground, it could be an issue.

I will keep an eye on them. I have gotten so used to seeing that witness mark on the shocks I just move on. Not any more. I honestly cant say I have seen it on the newer ones.Like I said I destroyed my bump stops the first year and no contact but the geometry changed a bit with the 19'-20's so it may not happen with the newer ones?

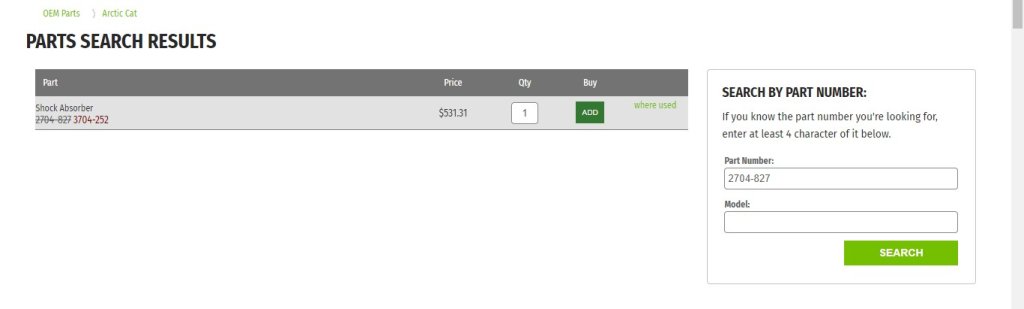

Part # of both cracked shocks I have here is 2704-827 maybe we should start a list of ones with witness mark?

Part search shows it is used on 2016 to current but somewhere in there the part # changed to 3704-252. What was changed? Perhaps threads were change to prevent this or eyelet moved slightly? They look Identical. The cracked body tube is known issue.

www.arcticcatpartshouse.com

www.arcticcatpartshouse.com

Part search shows it is used on 2016 to current but somewhere in there the part # changed to 3704-252. What was changed? Perhaps threads were change to prevent this or eyelet moved slightly? They look Identical. The cracked body tube is known issue.

OEM Parts Part Search Results

Last edited:

hellflyer

TY 4 Stroke Master

- Joined

- Dec 2, 2008

- Messages

- 1,086

- Location

- Georgtown ONT. Canada

- Country

- Canada

- Snowmobile

- 2020 sidewinder ltx se

They also add an extra tab on the lower link so you can't flip it upside down like so many people have

Right so lets assume the issue is corrected on newer ones with the 3704-252 shock. I am trying to say this without stepping on toes and hurting my relations with industry. The cracking bodies is a known issue. Either fix the contact point which I believe worsens a weak shock or buy the new 3704-252 shock which may or may not fix the issue of cracked body tube at threads. I know what I would do. Get out the grinder and paint and ride.They also add an extra tab on the lower link so you can't flip it upside down like so many people have

hellflyer

TY 4 Stroke Master

- Joined

- Dec 2, 2008

- Messages

- 1,086

- Location

- Georgtown ONT. Canada

- Country

- Canada

- Snowmobile

- 2020 sidewinder ltx se

100% grind and paint. All they had to do on the newer ones is move that lower shaft mount 1/4" forward. Wheels aren't on it anymore anyway.Right so lets assume the issue is corrected on newer ones with the 3704-252 shock. I am trying to say this without stepping on toes and hurting my relations with industry. The cracking bodies is a known issue. Either fix the contact point which I believe worsens a weak shock or buy the new 3704-252 shock which may or may not fix the issue of cracked body tube at threads. I know what I would do. Get out the grinder and paint and ride.

Vs grinding the tube it would lose travel. Bumpstop compression is part of travel. Nothing should hit even with bumpstops completely removed. At least that’s how a proper suspension is designed.

If you take the perspective that the skid should travel that far then yes, grinding keeps travel the same. If you take the position that the suspension should stop before that hit happens, then the bumpstop should be the point at which the suspension stops. I would argue that the entire point of the bumpstop is to stop this from happening. Raising the bumpstop would be the right answer. BUT....

Looking at this a bit closer, I think this is shock specific. I just had a look at my 21 and t

The IQS shocks have the reservoir bracket at an angle away from the eye where the shock attaches, not perpendicular to the shock body like the QS3.

QS3, reservoir bracket extends perpendicular from shock body

IQS, you can see how the angle of the reservoir creates clearance.

Also, the eyelet itself sticks out further

Similar threads

- Replies

- 26

- Views

- 7K

- Replies

- 48

- Views

- 11K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.