Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

I'm on it...You can use whatever plug you want, but I use NGK CR9EK dual ground electrode plugs myself. They are dual ground electrode plugs and one step colder than stock plugs.

If you can hear the pump working key on, but engine off, I suspect the pickups in the tank or the internal pressure hose to be the culprit.

Definitely, pretty sure they got loaded up in the 45 minutes it took me to load it at the bottom of the ramp to the truck. Then another 45 minutes to get it off the truck and into the shed.Hope you got spark plugs at auto zone. Even thought they may be good it would still be worthwhile to put some new ones in before tearing into the fuel system.

I'll grab a set tomorrow

Trailleader

Expert

did you reuse that plastic line?

If you need anything pm me and you can call

I have a 998 sitting in the corner on time out still

Lol

Parts

If you need anything pm me and you can call

I have a 998 sitting in the corner on time out still

Lol

Parts

Start simple:

-Thaw it out in a warm garage

-check throttle cable adjustment for possible TORS issue

-ensure fuel pump is working by sound and pulling return line to ensure flow

-install new plugs

-check for restricted or pugged intake

-check all boost tubes are in place and intact especially to the turbo

-check vacuum lines to solenoids are intact and not full of oil or condensation

-check wires are connected still to solenoids

-Thaw it out in a warm garage

-check throttle cable adjustment for possible TORS issue

-ensure fuel pump is working by sound and pulling return line to ensure flow

-install new plugs

-check for restricted or pugged intake

-check all boost tubes are in place and intact especially to the turbo

-check vacuum lines to solenoids are intact and not full of oil or condensation

-check wires are connected still to solenoids

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

No, I replaced with like. Maybe I didn't he shrink it good enough. Idk, just saying.did you reuse that plastic line?

If you need anything pm me and you can call

I have a 998 sitting in the corner on time out still

Lol

Parts

Maybe you should give me your address and throw that stuff at the end of your driveway. Hahaha....

Some good info, Bob... TyStart simple:

-Thaw it out in a warm garage

-check throttle cable adjustment for possible TORS issue

-ensure fuel pump is working by sound and pulling return line to ensure flow

-install new plugs

-check for restricted or pugged intake

-check all boost tubes are in place and intact especially to the turbo

-check vacuum lines to solenoids are intact and not full of oil or condensation

-check wires are connected still to solenoids

NYTurbo

TY 4 Stroke God

When you crank it over does it sound like it’s trying but won’t catch ?

IVe learned the hard way that some vendor used less than adequate fuel line for their pump upgrade and in short time they split. After the second occurrence I supplied my own fuel line on pump upgrades. This is where I’d start by doing visual on your fuel pump install as others have suggested. The sd26 code is puzzling though

IVe learned the hard way that some vendor used less than adequate fuel line for their pump upgrade and in short time they split. After the second occurrence I supplied my own fuel line on pump upgrades. This is where I’d start by doing visual on your fuel pump install as others have suggested. The sd26 code is puzzling though

Last edited:

bleedyamaha

TY 4 Stroke Master

- Joined

- Sep 28, 2013

- Messages

- 1,490

- Location

- Northern Iowa

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder Rtx Le 2012 Yamaha Vector Ltx

Is it cold enough to be a frozen relay?

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,050

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Sd 26 code I have had and cleared. Possibly caused by a lean condition on tuned sleds causing computer to register and overboost condition.

Trailleader

Expert

Let me know if you need any help and I’ll be back in il tomorrow afternoon

Have to leave n Wi to head south to the snow belt lol

I have a pump that’s the upgrade hurricane had on the bench and also a pefi pump upgrade on the bench in the housing

Have to leave n Wi to head south to the snow belt lol

I have a pump that’s the upgrade hurricane had on the bench and also a pefi pump upgrade on the bench in the housing

Last edited:

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,862

- Age

- 46

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

Lucky you lol.. I got a sd26 code but stayed on and it was a major pain to get it cleared.Sd 26 code I have had and cleared. Possibly caused by a lean condition on tuned sleds causing computer to register and overboost condition.

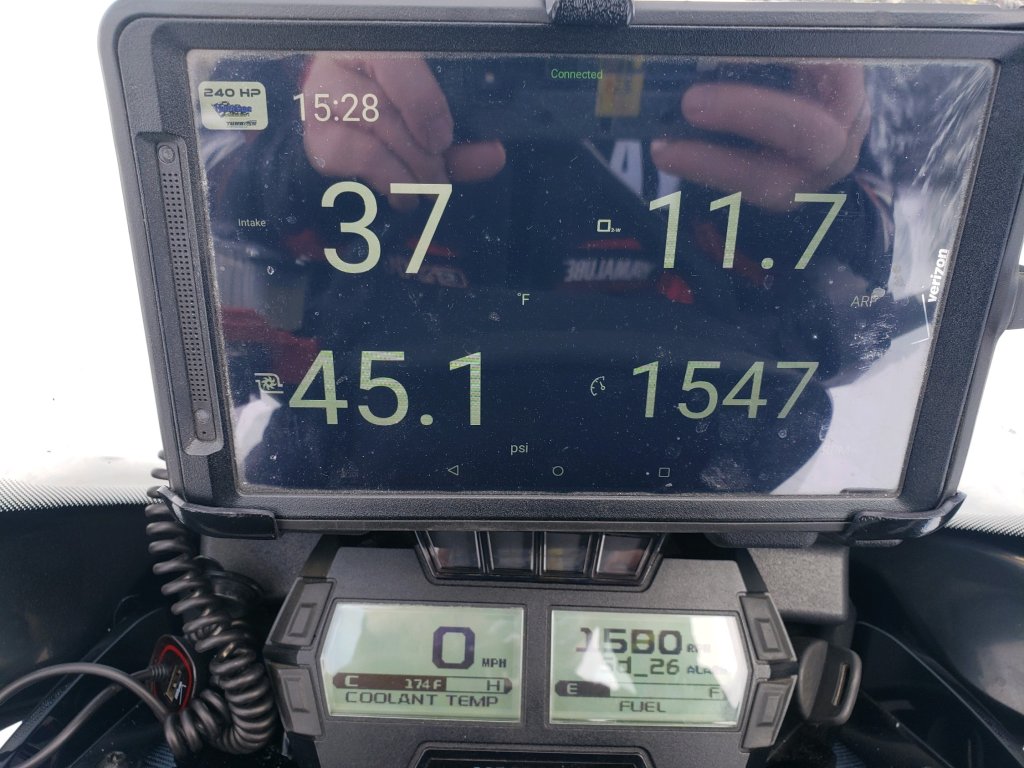

View attachment 175033

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

When you crank it over does it sound like it’s trying but won’t catch ?

IVe learned the hard way that some vendor used less than adequate fuel line for their pump upgrade and in short time they split. After the second occurrence I supplied my own fuel line on pump upgrades. This is where I’d start by doing visual on your fuel pump install as others have suggested. The sd26 code is puzzling though

NYTurbo, it turns over and starts immediately, but she'll die out if I don't try to keep pumping the throttle.Sd 26 code I have had and cleared. Possibly caused by a lean condition on tuned sleds causing computer to register and overboost condition.

View attachment 175033

1NC, this is exactly what I've been thinking. Loss of fuel caused lean condition thus throwing lite on. 90% sure this to be true, for me. I'll know more tomorrow when I pull the return line and let her spit into a bucket for a bit.

I still think I should put a gauge on her just to see what's going on.

32° today. Plus I have the better relays.Is it cold enough to be a frozen relay?

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

Storms getting bigger and bigger by the minute. So I'm thinking we're going to get at least 3" lol. Seriously I think we may get a good clip of snow on this one.Let me know if you need any help and I’ll be back in il tomorrow afternoon

Have to leave n Wi to head south to the snow belt lol

I have a pump that’s the upgrade hurricane had on the bench and also a pefi pump upgrade on the bench in the housing

I'll keep ya posted.... Thanks, Josh

Trailleader

Expert

How full is the tank?

When you reinstall the pump and banana you have to make sure the pickups go to bottom of the tank and I always took it the fuel level sensor to make sure of this

I have a stock map sensor 3 and 4 bars also if you don’t find an issue in the fueling

I assume it’s there.

When you reinstall the pump and banana you have to make sure the pickups go to bottom of the tank and I always took it the fuel level sensor to make sure of this

I have a stock map sensor 3 and 4 bars also if you don’t find an issue in the fueling

I assume it’s there.

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

Fuel lite came on traversing the 45° angle on the ramp. So I thought the same (low fuel) I added 2 gallons, no change.How full is the tank?

When you reinstall the pump and banana you have to make sure the pickups go to bottom of the tank and I always took it the fuel level sensor to make sure of this

I have a stock map sensor 3 and 4 bars also if you don’t find an issue in the fueling

I assume it’s there.

I'll go through the fuel system tomorrow. And will consider a three-bar map, as I know they've been up and down as to whether they work or not. Idk.

The fuel pump comes on and the sled will start. Just can't get enough fuel to move it. That's why I'm thinking either pump or fuel line (above pump )installed incorrectly.

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,758

- Age

- 50

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

You could plumb in a guage on the exit of the fuel rail.Derek,

With the lack of a Schrader valve is there no way to test fuel pressure, to diagnose ?

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,409

- Age

- 55

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

I'm just going to buy (if needed) the gauge from harbor freight and then plug it right into the top of the pump.You could plumb in a guage on the exit of the fuel rail.

The gauge from harbor freight has a bleed off to allow fuel to keep moving.

I'm sure I can make something but it's only $32.

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.